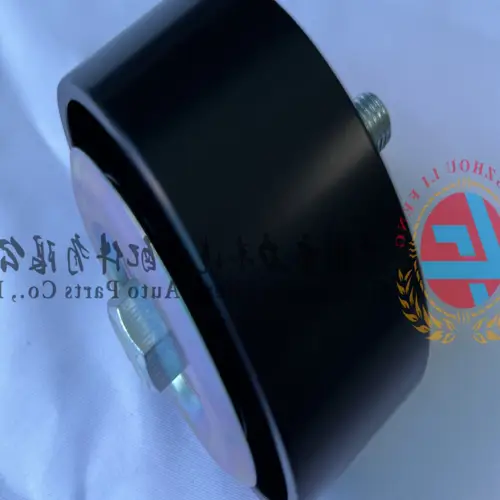

China Manufacturer Car 20t Aluminium Timing Drive Pulley Air Compressor Portable

Product Description

Introducing our high-quality Timing Belt Pulley, designed to meet your specific needs. Manufactured with precision, our pulleys are reliable and durable, making them perfect for various industrial applications. Here are the specifications:

Specifications:

- Type: Timing Belt Pulley

- Certificate: ISO9001

- Teeth Profile: 5M, 8M, MXL, XL, L, H, 2M, S2M, 3M, S3M, 5M, 8M, 14M, T2.5, T5

- Belt Width: 4-50mm

- Inner Bore: 2-200mm H7 precision or customized

- Bore Type: Taper hole, pilot bore, round hole

- Color: OEM

- Surface Treatment: Anodize, Black Oxide, Phosphate, and Galvanization

Our company specializes in supplying a wide range of industrial products, including agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, roller chains, pulleys, planetary gearboxes, timing pulleys, bushings, and more. Our products are known for their high quality, competitive prices, and exceptional customer service. We also offer customization options to meet your specific requirements.

Frequently Asked Questions (FAQs)

Q1: Can I request a sample order for Timing Belt Pulley?

A1: Yes, we welcome sample orders for you to test and evaluate the quality of our Timing Belt Pulleys. We also accept mixed samples.

Q2: What is the lead time for orders?

A2: The lead time for sample orders is 2-3 days. For mass production, it usually takes 20-30 days. However, if you have an urgent request, we have a special fast track to prioritize your order.

Q3: Is there a minimum order quantity (MOQ) for V belt orders?

A3: We have a low MOQ policy, and you can place an order for as low as 1 piece to check the sample's quality.

Q4: Can I customize V belt products with my logo?

A4: Absolutely! We can print your logo or design on our V belt products. Kindly provide us with your logo or design details before we begin the mass production process.

Q5: How do you ensure the quality of your products?

A5: As one of the top suppliers to international famous belt companies for many years, our commitment to excellence and quality has been widely recognized. You can trust in the superior quality of our products.

Contact us today for more information and to discuss your specific requirements. We look forward to serving you with our high-quality products, competitive prices, and exceptional customer support.

All the content of this page is from the Internet, the content is only as a reference for product selection. Our products are replacement parts and not original spare parts. We are not the holder of the original trademarks of the content. Our products are only suitable for after-sales replacement parts and not original spare parts. Our replacement parts can be perfectly adapted to the original spare parts. If you need to buy original spare parts, please contact the original factory to buy. If you want to buy original spare parts, please contact the original supplier for purchase.

Performance Characteristics of Car Pulley

Car pulleys are essential components in a vehicle's engine system. They serve various purposes and offer several performance characteristics that contribute to the overall efficiency of the system.

1. High Durability: Car pulleys are designed to withstand the demanding conditions of engine operation, ensuring long-lasting performance.

2. Smooth Operation: These pulleys are precisely engineered to minimize friction and vibrations, resulting in smooth and efficient power transmission.

3. Noise Reduction: Car pulleys are designed to minimize noise during operation, providing a quieter driving experience.

4. Enhanced Efficiency: By optimizing power transmission, car pulleys help increase the overall efficiency of the engine system, leading to improved fuel economy.

Types and Characteristics of Car Pulley

There are various types of car pulleys, each with its own unique characteristics.

1. Belt-Driven Pulleys: These pulleys are commonly used in accessory systems such as the alternator, power steering, and air conditioning. They are known for their smooth operation and reliable performance.

2. Timing Belt Pulleys: These pulleys are crucial in the engine's timing system, ensuring precise synchronization between the crankshaft and camshaft. They are designed to withstand high temperatures and provide accurate timing.

3. Serpentine Belt Pulleys: Found in modern vehicles, serpentine belt pulleys are responsible for driving multiple accessories simultaneously. They offer efficient power transmission and improved space utilization.

Advantages of Different Materials for Car Pulley

Car pulleys can be made from various materials, each offering its own set of advantages.

1. Aluminum Pulleys: Lightweight and corrosion-resistant, aluminum pulleys reduce the overall weight of the engine system, resulting in improved fuel efficiency.

2. Steel Pulleys: Known for their high strength and durability, steel pulleys are commonly used in heavy-duty applications where reliability is crucial.

3. Composite Pulleys: These pulleys combine the benefits of different materials, offering a balance between strength, weight, and cost. They are often used in modern vehicles for their versatility.

Application of Car Pulley in Various Systems

Car pulleys play a vital role in various systems within a vehicle. Their application extends beyond just the engine system, as they are utilized in several other areas:

1. Engine Systems: Car pulleys are crucial components in the engine's timing system, ensuring precise synchronization and optimal performance.

2. Accessory Systems: Pulleys are used in accessory systems such as power steering, air conditioning, and alternators, providing power to these components for smooth operation.

3. Transmission Systems: Car pulleys are utilized in transmission systems to facilitate smooth gear shifting and efficient power transmission.

4. Fuel Systems: Certain types of pulleys are used in fuel systems, ensuring proper delivery of fuel to the engine for optimal combustion.

5. Auxiliary Systems: Car pulleys are also employed in auxiliary systems such as water pumps and superchargers, contributing to their efficient operation.

Future Development Trends and Opportunities

The car pulley industry is constantly evolving, and there are several future development trends and opportunities to consider.

1. Lightweight Materials: With the increasing demand for fuel efficiency, the use of lightweight materials in car pulleys is expected to grow, resulting in improved overall performance.

2. Advanced Manufacturing Techniques: The adoption of advanced manufacturing techniques, such as 3D printing, can enhance the precision and efficiency of car pulley production.

3. Electric Vehicle Integration: As electric vehicles gain popularity, there will be opportunities to develop specialized pulleys for electric drivetrains, optimizing their performance and efficiency.

4. Smart Pulley Systems: The integration of sensors and intelligent control systems into car pulleys can enable real-time monitoring and adjustment, further optimizing performance and minimizing maintenance.

How to Choose a Suitable Car Pulley

Choosing the right car pulley is essential to ensure optimal performance and longevity. Consider the following aspects when selecting a suitable pulley:

1. Load Capacity: Determine the maximum load the pulley will need to withstand to ensure it can handle the demands of the specific application.

2. Material: Select a pulley material that suits the application's requirements, considering factors such as durability, weight, and corrosion resistance.

3. Diameter and Size: Choose a pulley with the appropriate diameter and size to ensure proper fit and compatibility with other components.

4. Type of Pulley: Consider the specific type of pulley required for the system, such as a timing belt pulley or serpentine belt pulley, based on the vehicle's specifications.

5. Bore Size: Ensure that the pulley's bore size matches the shaft diameter to ensure secure and accurate installation.

Summary

Car pulleys are integral components in a vehicle's engine and various systems. They offer performance characteristics such as durability, smooth operation, noise reduction, and enhanced efficiency. Different types of pulleys, made from materials like aluminum, steel, and composites, have their own advantages. Car pulleys find applications in engine systems, accessory systems, transmission systems, fuel systems, and auxiliary systems, showcasing their value and importance. The future of car pulleys lies in lightweight materials, advanced manufacturing techniques, electric vehicle integration, and smart pulley systems. When selecting a suitable car pulley, consider factors such as load capacity, material, diameter and size, type of pulley, and bore size. Choose wisely to ensure optimal performance and compatibility.

Author: Dream