Product Description

Product Description

Production Descopriton

Product Parameters

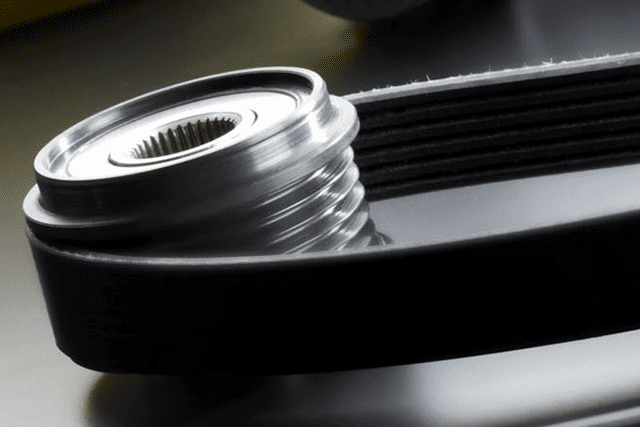

| Production Model | NYLON Pulley | Size | 320mm 400mm 480mm 500mm |

| Material | Nylon , Iron |

Packaging & Shipping

Company Profile

•ISO9001

•Well made products and very competitive price

•Near ZheJiang Port(one of biggest port in china)

HangZhou CHINAMFG Elevator Accessories Co.,Ltd is equipped with the world's first-class production equipments,the internationalized production workshops and the large-scale assembly flow including the advanced laser cutter imported from the United States.The work-piece cutting fulfills the more attractive and more accurate conditions.The highly effective,precise and intellectual runn ing modes ensure that LEFENG elevator are well-received by vast users over the years.

Our factory supply all compents of elevator,such as controller,traction motor,door operator and landing door,guide rail,guide shoes,cabin and etc. We also supply OEM elevator and complete elevator,passenger elevator,home lift,cargo elevator,car lift,panoramic elevator,hospital elevator.

FAQ

Q1. What is your terms of packing?

Re: Generally, we packed our goods by CHINAMFG wood case. But if you have legally registered patent, we can pack the goods in your branded boxes after getting your authorization letters.

Q2. What is your terms of delivery?

Re: EXW, FOB, CFR, CIF.

Q3. How about your delivery time?

Re: Generally, it will take 25 to 30 days after you confirm the elevator (escalator) specification and drawing, and receiving your advance payment.

Q4.What's the necessary information should be provided before purchasing an elevator?

Re:1).How many people loading? (6persons means 450kg, 8persons means 630kg, 10persons means 800kg,13persons means 1000kg etc.) 2).How many floors does the elevator travel?3).What's the shaft size? Shaft width and shaft depth?

4).Is there a machine room on top of the shaft? When we get the answers, we can design exact elevator and make an quotation to you.

Q5.How to do the elevator installation and maintenance?

Re: Normally, local people can do that job with our provided manuals and technology support. You can ask the local professional elevator engineers or technician to install elevators for you, that's the long time solution. You can also ask our engineers to go to your site to do that job but the cost will be much higher and maintenance job will be still given to local people for the rest time after installation.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Technical Supports ,Free Small Parts Changes |

|---|---|

| Warranty: | 12months |

| Type: | Safety System |

| Suitable for: | Elevator |

| Load Capacity: | 1000kg |

| Persons: | 6-10 |

| Customization: |

Available

| Customized Request |

|---|

Can car pulleys be a source of noise or vibration in a vehicle?

Yes, car pulleys can indeed be a source of noise or vibration in a vehicle. Several factors related to the pulleys can contribute to noise and vibration issues. Here's a detailed explanation:

Pulley Misalignment:

If the car pulleys are not properly aligned with other components, such as belts or accessories, it can cause misalignment-related problems. Misaligned pulleys can lead to increased friction, belt wear, and uneven power transmission. This can result in noise and vibration in the vehicle. Common causes of pulley misalignment include improper installation, worn-out components, or damage to the pulley system.

Worn-out or Damaged Pulley Bearings:

The pulleys in a vehicle incorporate bearings that allow smooth rotation. Over time, these bearings can wear out or become damaged, resulting in increased friction or play. Worn-out or damaged pulley bearings can lead to noise and vibration issues. The noise may manifest as squeaking, grinding, or rumbling sounds, especially when the pulley is rotating. Additionally, the vibration caused by faulty bearings can be felt through the vehicle's steering wheel or other components.

Belt Tension and Condition:

The tension of the belts connected to the pulleys is crucial for their proper operation. If the belt tension is too loose or too tight, it can cause problems. A loose belt may slip on the pulley, resulting in noise and vibration. On the other hand, an excessively tight belt can put excessive strain on the pulley and other components, leading to noise and vibration as well. Furthermore, worn-out or damaged belts can also contribute to noise issues when they interact with the pulleys.

Accessory Component Issues:

In addition to the pulleys themselves, noise and vibration can also be caused by issues with the accessory components driven by the pulley system. For example, a malfunctioning alternator, power steering pump, air conditioning compressor, or water pump can generate noise or vibration that is transmitted through the pulleys. Such issues may be related to worn-out bearings, unbalanced components, or internal mechanical problems.

Other Factors:

It's important to note that while car pulleys can contribute to noise and vibration, they are not the sole potential source. Other factors such as engine problems, exhaust system issues, suspension components, or tire irregularities can also cause noise and vibration in a vehicle. Therefore, a comprehensive diagnosis is necessary to identify the exact source of the noise or vibration.

In summary, car pulleys can be a source of noise or vibration in a vehicle. Pulley misalignment, worn-out or damaged bearings, improper belt tension, and issues with accessory components can all contribute to these problems. If you experience unusual noise or vibration in your vehicle, it is advisable to have it inspected by a qualified mechanic to identify and address the underlying cause.

How do car pulleys contribute to the overall fuel efficiency of a vehicle?

Car pulleys play a significant role in the overall fuel efficiency of a vehicle. They contribute to the efficient operation of various engine-driven components and help reduce parasitic losses. Here's a detailed explanation of how car pulleys contribute to the overall fuel efficiency of a vehicle:

- Reduced Parasitic Drag: Car pulleys are responsible for driving accessories such as the alternator, power steering pump, air conditioning compressor, and water pump. These accessories draw power from the engine, creating parasitic drag that consumes fuel. Efficiently designed and properly tensioned pulleys minimize the resistance encountered by these accessories, reducing the amount of power required to operate them and minimizing fuel consumption.

- Optimized Power Delivery: Pulleys help optimize power delivery to the driven components. Properly sized and aligned pulleys ensure that the engine's power is efficiently transferred to the accessories without unnecessary energy losses. This allows the accessories to operate at their intended speeds and power requirements, minimizing the need for additional energy and improving overall fuel efficiency.

- Improved Throttle Response: Car pulleys can enhance throttle response, which indirectly affects fuel efficiency. Lighter pulleys with reduced rotational inertia can reduce the time it takes for the engine to respond to throttle inputs. This improved response allows for more precise control over the engine's power output, enabling drivers to modulate their acceleration and maintain efficient fuel consumption during various driving conditions.

- Efficient Cooling System Operation: The water pump, driven by a pulley, circulates coolant throughout the engine to maintain optimal operating temperatures. Properly functioning pulleys ensure that the water pump operates at the appropriate speed, delivering sufficient coolant flow for efficient engine cooling. This prevents overheating and the need for fuel-consuming measures, such as running the cooling fans at higher speeds, to maintain engine temperature.

- Optimal Charging System Performance: The alternator, driven by a pulley, is responsible for charging the vehicle's battery and providing electrical power to various electrical systems. Well-maintained pulleys ensure that the alternator operates at the correct speed, generating the necessary electrical power without excessive strain on the engine. This helps maintain the battery's charge, reducing the need for frequent recharging and optimizing fuel efficiency.

- Proper Power Steering Function: The power steering pump, driven by a pulley, assists in steering effort by providing hydraulic power. Smooth and efficient operation of the power steering system reduces the strain on the engine and minimizes fuel consumption. Well-maintained pulleys ensure that the power steering pump operates optimally, supporting efficient power assistance and reducing unnecessary power draw from the engine.

In summary, car pulleys contribute to the overall fuel efficiency of a vehicle by reducing parasitic drag, optimizing power delivery, improving throttle response, facilitating efficient cooling system operation, enabling optimal charging system performance, and supporting proper power steering function. Proper maintenance, alignment, and tensioning of pulleys are essential to ensure their efficient operation, minimize energy losses, and maximize fuel efficiency.

How does the size and design of a car pulley impact engine performance?

The size and design of a car pulley have a significant impact on engine performance. The pulley's size and design influence critical factors such as power output, torque characteristics, component speeds, and efficiency. Here's a detailed explanation of how the size and design of a car pulley impact engine performance:

- Power Output: The size of the pulley directly affects the power output of the engine. A larger pulley on the crankshaft will result in a slower rotational speed, reducing the power output. Conversely, a smaller pulley will increase the rotational speed and potentially boost power output. Modifying the size of the pulley can be used to fine-tune the engine's power delivery characteristics and optimize performance for specific applications.

- Torque Characteristics: The size and design of the pulley impact the torque characteristics of the engine. A smaller pulley can increase the torque at lower engine speeds, providing better low-end responsiveness and acceleration. On the other hand, a larger pulley can improve top-end torque, allowing for higher speeds. The choice of pulley size and design should consider the desired torque curve and the engine's intended use.

- Component Speeds: The size and design of pulleys affect the rotational speeds of various engine components. For example, the size of the crankshaft pulley determines the speeds at which the driven components, such as the alternator, water pump, and power steering pump, operate. Proper sizing and design ensure that the components operate within their optimal speed ranges, maximizing their efficiency and performance.

- Belt Tension and Slippage: The size and design of the pulley influence the tension and potential slippage of the belts connected to it. A properly sized pulley ensures the correct tension in the belts, preventing excessive slippage that can lead to power loss and reduced efficiency. The pulley's design, including the shape and depth of the grooves, also plays a role in maintaining proper belt engagement and minimizing slippage.

- Efficiency: The size and design of the pulley impact the overall efficiency of the engine. An appropriately sized pulley helps optimize power transmission, minimizing energy losses due to belt slippage or excessive friction. Additionally, pulleys with well-designed grooves and smooth surfaces reduce friction, improving overall efficiency by reducing energy wastage and enhancing the engine's ability to convert fuel into useful work.

- Accessory Operation: The size and design of pulleys influence the operation of engine accessories. Properly sized pulleys ensure that the accessories, such as the alternator, power steering pump, and air conditioning compressor, operate at the correct speeds to provide optimal performance. A mismatch between pulley size and accessory requirements can lead to underperformance or excessive load on the engine.

In conclusion, the size and design of a car pulley have a significant impact on engine performance. They affect power output, torque characteristics, component speeds, belt tension, efficiency, and accessory operation. Careful consideration of pulley size and design is crucial in optimizing engine performance for specific requirements, balancing power, torque, and efficiency to achieve the desired performance characteristics.

editor by CX

2024-04-08