Product Description

Surface treatment for CNC Machining part:

| 1 | Zinc/nickel/chrome plating |

| 2 | hot galvanized |

| 3 | painting |

| 4 | powder coating |

| 5 | Anodize Oxidation, or with colors: like silver, blue, red, etc. |

| 6 | plating, silver-plated, Gold-plated, etc |

| 7 | polishing |

| 8 | electrolytic polishing |

| 9 | sank without electricity nickel |

| etc | etc. |

HangZhou CHINAMFG Machinery Co., Ltd. is located in HangZhou, HangZhou. Based on the advantages of specialized talents, it has formed 4 professional project sections with excellent technical equipment, sound quality assurance system and standardized production environment: mechanical processing, sheet metal stamping production, Mold manufacturing, high-speed rice transplanter, with the high recognition of the majority of mature customers, cast the "Xin Rifeng" brand in the industry's CHINAMFG position, and strive to build an intelligent manufacturing service system.

It is people-oriented, Difeng people focus on the production of high-quality rice transplanter planting department with high quality and advanced technology, all kinds of mold design, R&D and manufacturing required for sheet metal stamping; at the same time, develop continuous die and welding.

We always adhere to the customer's position to solve the problem, the product to achieve process optimization, reduce costs, and continue to reduce materials for the purpose, so for the domestic major Asian high-speed main engine factory and high-speed rice transplanter market, some products are sold to Pakistan, Vietnam, Countries and regions such as India. It has successively become an excellent supplier of domestic famous enterprises such as Japanese Yanmar, Japan Kubota, Nideko Electric, Hailiwei and ZheJiang Xihu (West Lake) Dis.. The company has successively obtained the "HangZhou Small and Medium-sized Specialized Special New Product (Technology) Certificate" and "ISO9001 Quality Certification" and successfully registered the "Xin Rifeng" trademark.

Workshop equipment

Certifications

Packaging & Shipping

FAQ

Q1: Are you a factory or a trading company?

A1: We are a professional manufacturer of CNC parts for over 14 years.

Q2: How can I get quotation?

A2: Please help to send drawing (2D and 3D drawing) to us, so we can know the raw material, size and surface treatment, tolerance and other details of the product. And also inform us the quantity you need.

Q3: What kind of material you can process?

A3: Normally Aluminum alloy and stainless steel, but we also can do titanium alloy steel, copper alloy steel special alloy steel and non-metal material.

Q4: What is the minimum size tolerance you can do?

A4: The minimum size tolerance we can do is 0.001mm.

Q5: What is the biggest range you can do?

A5: The biggest range we can do is 1500mm.

Q6: Can you do precise and complicated CNC parts?

A6: Yes, we can do precise and complicated CNC parts by our 5/4/3 axis CNC machines

Q7: Can you accept sample order?

A7: Yes, we can do sample order per your requirement.

Q8:Can you accept custom packing?

A8: Yes, we can do custom packing as your requirement.

| After-sales Service: | Lifelong After-Sales Service |

|---|---|

| Application: | Cow |

| Power Source: | Electric |

| Heating and Ventilation Equipment Type: | Hot Blast Stove |

| Epidemic Prevention Equipment: | Aerosol Immune Machine |

| Certification: | CE |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

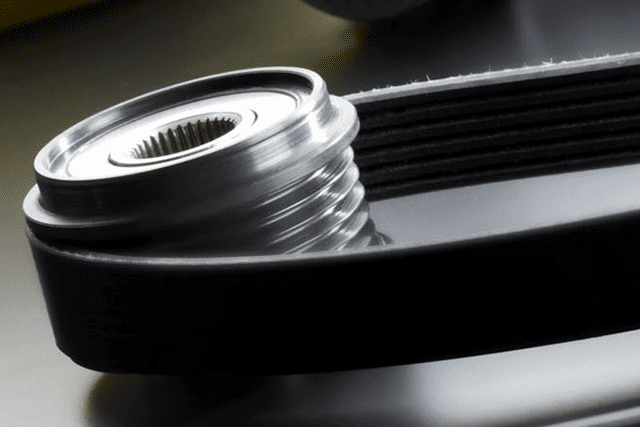

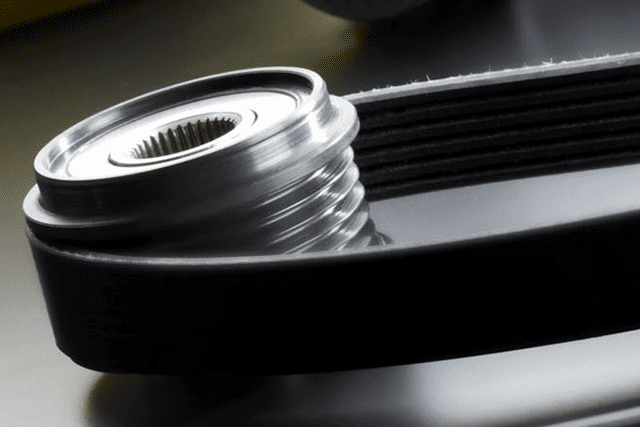

What safety considerations should be kept in mind when working with car pulleys?

Working with car pulleys involves potential hazards, and it's crucial to prioritize safety to prevent accidents or injuries. Here are some important safety considerations to keep in mind when working with car pulleys:

- Personal Protective Equipment (PPE): Always wear appropriate personal protective equipment, such as safety glasses/goggles, gloves, and protective clothing. PPE helps protect against potential hazards like flying debris, sharp edges, or chemical exposures. Ensure that your PPE is in good condition and fits properly.

- Engine Shutdown and Cooling: Before working with car pulleys, ensure that the engine is shut off and has had sufficient time to cool down. Hot engine components, including pulleys, can cause burns or other injuries. Allow the engine to cool to a safe temperature before carrying out any maintenance or repair work.

- Secure the Vehicle: Park the vehicle on a level surface and engage the parking brake to prevent any unintended movement. If necessary, use wheel chocks to further secure the vehicle and prevent rolling. Working on a stable and stationary vehicle minimizes the risk of accidents or injuries caused by unexpected vehicle movement.

- Disconnect the Battery: When working with pulleys connected to the electrical system, such as alternator pulleys, it's advisable to disconnect the vehicle's battery. This precaution helps prevent electrical shocks or short circuits. Refer to the vehicle's manual for specific instructions on disconnecting the battery safely.

- Use Proper Tools and Equipment: Ensure that you have the appropriate tools and equipment for the task at hand. Using improper tools or makeshift solutions can lead to accidents or damage to the pulley system. Follow the manufacturer's recommendations and instructions when using tools and equipment.

- Pulley Tension Release: If you need to release tension from a pulley, such as when removing a belt, follow the manufacturer's guidelines or repair manual instructions. Improperly releasing tension can cause sudden movements or accidents. Use the appropriate tools or techniques to release tension safely.

- Pulley Alignment: When installing or replacing pulleys, ensure proper alignment with other components, such as belts, accessories, or pulley grooves. Misaligned pulleys can cause belt slippage, improper power transmission, or premature component wear. Follow the manufacturer's instructions or consult a professional to ensure correct pulley alignment.

- Avoid Excessive Force: Use caution and avoid applying excessive force when working with pulleys. Excessive force can lead to sudden movements, component damage, or personal injury. If a pulley or component is difficult to remove or install, reassess the procedure and seek guidance if necessary.

- Proper Lifting Techniques: When lifting heavy pulleys or components, use proper lifting techniques to avoid strain or injury. Lift with your legs, not your back, and ask for assistance if needed. Use lifting equipment or devices when appropriate to ensure safe handling of heavy pulleys.

- Follow Repair Procedures: Adhere to proper repair procedures outlined in the vehicle's repair manual or manufacturer's guidelines. Following correct procedures ensures safe and effective repair or maintenance work. If you are unsure about any step, consult an experienced professional or seek guidance from reliable sources.

Remember, safety should always be the top priority when working with car pulleys or any other automotive components. By following these safety considerations and exercising caution, you can minimize the risk of accidents, injuries, or damage to the vehicle or yourself.

What role do car pulleys play in controlling and synchronizing engine components?

Car pulleys play a crucial role in controlling and synchronizing engine components, ensuring their proper operation and coordination. They are responsible for transmitting power from the engine's crankshaft to various driven components and systems. Here's an in-depth explanation of the role car pulleys play in controlling and synchronizing engine components:

- Power Transmission: Car pulleys, in conjunction with belts or chains, transmit rotational power from the engine's crankshaft to driven components and systems. The pulleys are connected to the crankshaft and rotate as the engine runs. As the crankshaft pulley turns, it drives the belts or chains that are connected to other pulleys located on components such as the alternator, power steering pump, air conditioning compressor, water pump, and more. This power transmission enables these components to function and perform their respective tasks.

- Belt Routing: Car pulleys play a critical role in determining the routing of belts throughout the engine. The pulley locations and orientations are carefully designed to ensure the most efficient and appropriate path for the belts to wrap around. Proper belt routing enables the pulleys to drive the desired components without interference, minimizing the risk of belt slippage, misalignment, or contact with other engine parts.

- Tension Control: Car pulleys contribute to controlling the tension in belts or chains. Tension is crucial to ensure proper power transmission and prevent slippage. Some pulleys incorporate tensioner mechanisms that automatically adjust the tension in the belts to compensate for wear and stretch over time. These tensioners help maintain optimal belt tension, ensuring reliable power delivery to the driven components.

- Timing and Synchronization: In engines with overhead camshafts (OHC), car pulleys play a vital role in controlling the timing and synchronization of valve operation. The pulleys are connected to the camshafts, which open and close the engine's valves. The timing and synchronization of valve operation are critical for proper combustion and engine performance. Timing pulleys, often toothed or geared, ensure precise timing and synchronization between the crankshaft and camshaft(s), enabling efficient intake and exhaust valve operation.

- Accessory Operation: Car pulleys facilitate the operation of various engine accessories. The pulleys connected to components like the alternator, power steering pump, and air conditioning compressor enable these accessories to receive power and perform their functions. By controlling the rotational speed and power delivery, the pulleys ensure that the accessories operate at the required speeds and provide the necessary power for optimal performance.

- Harmonic Balancing: Some car pulleys, particularly the crankshaft pulley, incorporate harmonic balancers or dampers. These components help reduce vibrations and torsional forces generated by the engine's reciprocating motion. The harmonic balancer absorbs and dissipates these vibrations, protecting the engine and its components from excessive wear and potential damage.

In summary, car pulleys play a vital role in controlling and synchronizing engine components. They facilitate power transmission, control belt routing, adjust belt tension, ensure timing and synchronization of valve operation, enable accessory operation, and contribute to harmonic balancing. Properly designed and maintained pulleys are essential for the reliable and efficient operation of engine components, ensuring smooth coordination and optimal performance of the engine as a whole.

How does the size and design of a car pulley impact engine performance?

The size and design of a car pulley have a significant impact on engine performance. The pulley's size and design influence critical factors such as power output, torque characteristics, component speeds, and efficiency. Here's a detailed explanation of how the size and design of a car pulley impact engine performance:

- Power Output: The size of the pulley directly affects the power output of the engine. A larger pulley on the crankshaft will result in a slower rotational speed, reducing the power output. Conversely, a smaller pulley will increase the rotational speed and potentially boost power output. Modifying the size of the pulley can be used to fine-tune the engine's power delivery characteristics and optimize performance for specific applications.

- Torque Characteristics: The size and design of the pulley impact the torque characteristics of the engine. A smaller pulley can increase the torque at lower engine speeds, providing better low-end responsiveness and acceleration. On the other hand, a larger pulley can improve top-end torque, allowing for higher speeds. The choice of pulley size and design should consider the desired torque curve and the engine's intended use.

- Component Speeds: The size and design of pulleys affect the rotational speeds of various engine components. For example, the size of the crankshaft pulley determines the speeds at which the driven components, such as the alternator, water pump, and power steering pump, operate. Proper sizing and design ensure that the components operate within their optimal speed ranges, maximizing their efficiency and performance.

- Belt Tension and Slippage: The size and design of the pulley influence the tension and potential slippage of the belts connected to it. A properly sized pulley ensures the correct tension in the belts, preventing excessive slippage that can lead to power loss and reduced efficiency. The pulley's design, including the shape and depth of the grooves, also plays a role in maintaining proper belt engagement and minimizing slippage.

- Efficiency: The size and design of the pulley impact the overall efficiency of the engine. An appropriately sized pulley helps optimize power transmission, minimizing energy losses due to belt slippage or excessive friction. Additionally, pulleys with well-designed grooves and smooth surfaces reduce friction, improving overall efficiency by reducing energy wastage and enhancing the engine's ability to convert fuel into useful work.

- Accessory Operation: The size and design of pulleys influence the operation of engine accessories. Properly sized pulleys ensure that the accessories, such as the alternator, power steering pump, and air conditioning compressor, operate at the correct speeds to provide optimal performance. A mismatch between pulley size and accessory requirements can lead to underperformance or excessive load on the engine.

In conclusion, the size and design of a car pulley have a significant impact on engine performance. They affect power output, torque characteristics, component speeds, belt tension, efficiency, and accessory operation. Careful consideration of pulley size and design is crucial in optimizing engine performance for specific requirements, balancing power, torque, and efficiency to achieve the desired performance characteristics.

editor by CX

2023-09-29