Product Description

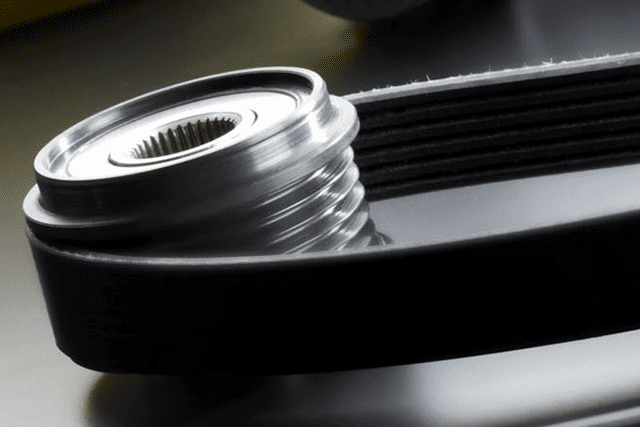

| Product name | Hanging Door Rollers Car Engine Pulley Heavy Duty Rope Pulley |

| Model number | Door Roller |

| Bore size | 5-10mm |

| Outside size | 5-5mm |

| Bearing material | Chrome steel, carbon steel, iron, high carbon steel |

| MOQ | 50000 PCS |

| Price terms | EXW, FOB, CIF |

| Payment terms | T/T, L/C, Paypal, Credit card |

| Production time | Depends on the quantity, normally 35-45 days. |

| Package | PE bag+white box+outer carton+pallet, or as customers' requirement. |

| Application | Used in door, window, furniture and sports equipment. |

1. Pre-sale service: Our professional sales will reply your inquiry within 48 hours and introduce the structure and usage of the products.

2. On-purchase service: After customers placed the order, we will prepare the goods ASAP to make sure the delivery on time. Any delay will be notified in advance.

3. After-sale service: If there is any damage during delivery, the cost will be taken by our company and if there is problem during the warranty period, we will replace or refund it.

4. OEM service: We have advanced technology and experienced technicians to support the professional customized all kinds of bearing to meet different requirements.

Q: Are your company is a trading company or manufacturer?

A:We have our own factory as well we do the trade by our selves.

Q:How long is your delivery time?

A:Usually 5-10 days if we have the stock,if not,it will be 25-35 days. But it always depend on the quantity.

Q:Do you provide the free samples?

A:Yes,we'd like to.But you need to pay the freight fee,or we will return the cost when receiving your order.

Q:Can you do the OEM/ODM services?

A:Of course we can,We can be customized according to your requirements or drawings.

| Certification: | CE |

|---|---|

| Splittable: | Splittable |

| Material: | Nylon |

| Groove Diameter: | Customized |

| Inner Hole: | 5-10mm |

| Color: | Orange, Balck, Green, Yellow, Red,Blue |

| Samples: |

US$ 0.25/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What are some common issues or symptoms of car pulley problems?

Car pulley problems can manifest in various ways, and recognizing the symptoms is important for diagnosing and addressing the issues promptly. Here are some common issues or symptoms that indicate potential car pulley problems:

- Squealing or Screeching Noises: One of the most noticeable symptoms of pulley problems is the presence of squealing or screeching noises. If a pulley is misaligned, worn out, or damaged, it may cause the belt to slip or rub against the pulley's edges. This friction generates a high-pitched noise, often heard during engine startup, acceleration, or when the accessories are in operation.

- Excessive Belt Wear: Pulley problems can lead to excessive wear on the belts. Misaligned or damaged pulleys may cause the belts to run at an angle or make contact with other components, resulting in uneven wear. You may notice fraying, cracking, or signs of belt deterioration. Excessive belt wear can also be caused by insufficient tensioning, leading to belt slippage and accelerated wear.

- Belt Slippage: If a pulley is not properly tensioned or if the tensioner mechanism is faulty, belt slippage can occur. This is characterized by a momentary loss of power to the driven components, resulting in decreased performance or functionality. Belt slippage may cause accessories like the alternator or power steering pump to operate erratically or intermittently, leading to dimmed lights, loss of power assistance, or other related issues.

- Overheating: A malfunctioning water pump pulley can result in inadequate coolant circulation, leading to engine overheating. If the water pump pulley is damaged or the bearings within it are worn out, the water pump may not spin efficiently, reducing the coolant flow. This can cause the engine temperature to rise, potentially leading to overheating, increased coolant loss, and potential engine damage.

- Power Steering Issues: A faulty power steering pulley or tensioner can affect the operation of the power steering system. You may experience difficulty in steering, increased steering effort, or a jerky steering response. These symptoms indicate potential problems with the power steering pulley, such as misalignment, damaged bearings, or inadequate tensioning.

- Battery Charging Problems: The alternator pulley plays a crucial role in charging the vehicle's battery. If the alternator pulley is damaged or not spinning properly, it can lead to insufficient charging, resulting in a drained or weak battery. Dimmed lights, flickering gauges, or frequent battery issues can indicate potential problems with the alternator pulley.

- Excessive Vibration: Misaligned or damaged pulleys can cause excessive vibration in the engine compartment. You may feel vibrations or shaking through the steering wheel, pedals, or the vehicle's body. Excessive vibration can indicate problems with pulley alignment, damaged bearings, or other related issues.

If you observe any of these symptoms, it is advisable to have your vehicle inspected by a qualified mechanic. They can assess the condition of the pulleys, belts, and other related components to diagnose the problem accurately. Timely identification and resolution of car pulley issues can help prevent further damage to the pulley system and associated components, ensuring the reliable operation of your vehicle.

What is the significance of proper alignment and tensioning in car pulley systems?

Proper alignment and tensioning are crucial factors in the functioning and reliability of car pulley systems. The alignment ensures that the pulleys are correctly positioned and oriented, while the tensioning ensures that the belts connecting the pulleys are appropriately tensioned. Here's a detailed explanation of the significance of proper alignment and tensioning in car pulley systems:

- Efficient Power Transmission: Proper alignment of the pulleys ensures that the belts maintain optimal contact with the pulley grooves. This allows for efficient power transmission from the engine to the driven components, such as the alternator, power steering pump, air conditioning compressor, and water pump. Misaligned pulleys can cause belt slippage, reducing power delivery and affecting the performance of these components.

- Prevention of Belt Wear and Damage: Correct alignment and tensioning help prevent excessive belt wear and damage. Misalignment can cause the belts to rub against the pulley edges or sides, leading to accelerated wear, fraying, or even belt failure. Improper tensioning can result in slippage, causing the belts to generate heat, wear unevenly, and potentially snap. Proper alignment and tensioning distribute the load evenly across the belts, minimizing wear and extending their lifespan.

- Reduced Noise and Vibration: Misaligned or improperly tensioned pulleys can result in increased noise and vibration. Misalignment causes the belts to oscillate or vibrate, generating noise and potentially creating an unpleasant driving experience. Proper alignment and tensioning reduce belt vibrations, resulting in smoother and quieter operation of the pulley system.

- Optimal Performance and Efficiency: Proper alignment and tensioning contribute to optimal performance and efficiency of the engine and the driven components. When the pulleys are aligned correctly, the belts operate at their designed angles, maximizing contact area and minimizing energy losses. This improves the overall efficiency of the system and ensures that the driven components receive the necessary power for optimal performance.

- Prevention of Component Damage: Misalignment and improper tensioning can place excessive stress on the pulleys and the driven components. This can lead to premature component failure, such as bearing damage, shaft wear, or seal leaks. Proper alignment and tensioning help distribute the loads evenly, reducing stress on the pulleys and components, and minimizing the risk of damage or failure.

- Enhanced Belt Life: Correct alignment and tensioning contribute to the longevity of the belts. When the pulleys are properly aligned, and the belts are adequately tensioned, the belts experience less stress, wear, and fatigue. This extends the lifespan of the belts, reducing the frequency of belt replacements and associated maintenance costs.

In conclusion, proper alignment and tensioning are essential for the reliable and efficient operation of car pulley systems. They ensure efficient power transmission, prevent belt wear and damage, reduce noise and vibration, optimize performance and efficiency, prevent component damage, and enhance the lifespan of the belts. Regular inspections and adjustments should be performed to maintain proper alignment and tensioning, ensuring the longevity and reliable functioning of the pulley system and its associated components.

How does the size and design of a car pulley impact engine performance?

The size and design of a car pulley have a significant impact on engine performance. The pulley's size and design influence critical factors such as power output, torque characteristics, component speeds, and efficiency. Here's a detailed explanation of how the size and design of a car pulley impact engine performance:

- Power Output: The size of the pulley directly affects the power output of the engine. A larger pulley on the crankshaft will result in a slower rotational speed, reducing the power output. Conversely, a smaller pulley will increase the rotational speed and potentially boost power output. Modifying the size of the pulley can be used to fine-tune the engine's power delivery characteristics and optimize performance for specific applications.

- Torque Characteristics: The size and design of the pulley impact the torque characteristics of the engine. A smaller pulley can increase the torque at lower engine speeds, providing better low-end responsiveness and acceleration. On the other hand, a larger pulley can improve top-end torque, allowing for higher speeds. The choice of pulley size and design should consider the desired torque curve and the engine's intended use.

- Component Speeds: The size and design of pulleys affect the rotational speeds of various engine components. For example, the size of the crankshaft pulley determines the speeds at which the driven components, such as the alternator, water pump, and power steering pump, operate. Proper sizing and design ensure that the components operate within their optimal speed ranges, maximizing their efficiency and performance.

- Belt Tension and Slippage: The size and design of the pulley influence the tension and potential slippage of the belts connected to it. A properly sized pulley ensures the correct tension in the belts, preventing excessive slippage that can lead to power loss and reduced efficiency. The pulley's design, including the shape and depth of the grooves, also plays a role in maintaining proper belt engagement and minimizing slippage.

- Efficiency: The size and design of the pulley impact the overall efficiency of the engine. An appropriately sized pulley helps optimize power transmission, minimizing energy losses due to belt slippage or excessive friction. Additionally, pulleys with well-designed grooves and smooth surfaces reduce friction, improving overall efficiency by reducing energy wastage and enhancing the engine's ability to convert fuel into useful work.

- Accessory Operation: The size and design of pulleys influence the operation of engine accessories. Properly sized pulleys ensure that the accessories, such as the alternator, power steering pump, and air conditioning compressor, operate at the correct speeds to provide optimal performance. A mismatch between pulley size and accessory requirements can lead to underperformance or excessive load on the engine.

In conclusion, the size and design of a car pulley have a significant impact on engine performance. They affect power output, torque characteristics, component speeds, belt tension, efficiency, and accessory operation. Careful consideration of pulley size and design is crucial in optimizing engine performance for specific requirements, balancing power, torque, and efficiency to achieve the desired performance characteristics.

editor by CX

2023-09-29