Product Description

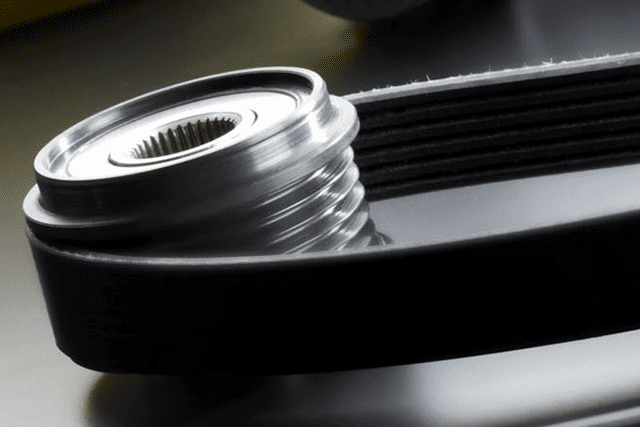

OEM 13408-75050 2571 Engine Car Part Crankshaft Pulley

Product Specification:

| Item Name | Crankshaft Pulley |

| Part Number | 13408-75050 |

| Material | Standard |

| Brand | FENGMING |

| MOQ | 1PCS |

| Warranty | 1 Year |

| Packing | 1.Original Packing 2. Neutral Packing 3. CHINAMFG brand Packing 4.Customized |

| Payment | L/C, T/T, Western Union, Cash,Paypal,Alipay |

| Delivery | 3-7 days for stock items, 15-25 days for production items |

| Shipment | by DHL/ FEDEX/ TNT, by sea,by air |

Customer Reviews:

Company Profile:

HangZhou CHINAMFG Import and Export Co.,Ltd,was established in 2018,which specializes in engine parts and chasis parts for Japanese cars,including spark plugs,auto filters,power steering rack,power steering pump,ignition coils,bushings,ABS sensors,bearing,brake pads,control arm etc.Our products have been exported to Europe and the United States, the Middle East and other international markets.We have consistently adhered to "quality of products in order to survive, credibility and development services" business purposes. We sincerely welcome you to visit our company or contact us for cooperation!

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Car |

|---|---|

| Certification: | ISO 9001 |

| Warranty: | 12 Months |

| Engine Type: | Diesel |

| Material: | Cast Iron |

| Product Name: | Crankshaft Pulley |

| Samples: |

US$ 16.5/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What safety considerations should be kept in mind when working with car pulleys?

Working with car pulleys involves potential hazards, and it's crucial to prioritize safety to prevent accidents or injuries. Here are some important safety considerations to keep in mind when working with car pulleys:

- Personal Protective Equipment (PPE): Always wear appropriate personal protective equipment, such as safety glasses/goggles, gloves, and protective clothing. PPE helps protect against potential hazards like flying debris, sharp edges, or chemical exposures. Ensure that your PPE is in good condition and fits properly.

- Engine Shutdown and Cooling: Before working with car pulleys, ensure that the engine is shut off and has had sufficient time to cool down. Hot engine components, including pulleys, can cause burns or other injuries. Allow the engine to cool to a safe temperature before carrying out any maintenance or repair work.

- Secure the Vehicle: Park the vehicle on a level surface and engage the parking brake to prevent any unintended movement. If necessary, use wheel chocks to further secure the vehicle and prevent rolling. Working on a stable and stationary vehicle minimizes the risk of accidents or injuries caused by unexpected vehicle movement.

- Disconnect the Battery: When working with pulleys connected to the electrical system, such as alternator pulleys, it's advisable to disconnect the vehicle's battery. This precaution helps prevent electrical shocks or short circuits. Refer to the vehicle's manual for specific instructions on disconnecting the battery safely.

- Use Proper Tools and Equipment: Ensure that you have the appropriate tools and equipment for the task at hand. Using improper tools or makeshift solutions can lead to accidents or damage to the pulley system. Follow the manufacturer's recommendations and instructions when using tools and equipment.

- Pulley Tension Release: If you need to release tension from a pulley, such as when removing a belt, follow the manufacturer's guidelines or repair manual instructions. Improperly releasing tension can cause sudden movements or accidents. Use the appropriate tools or techniques to release tension safely.

- Pulley Alignment: When installing or replacing pulleys, ensure proper alignment with other components, such as belts, accessories, or pulley grooves. Misaligned pulleys can cause belt slippage, improper power transmission, or premature component wear. Follow the manufacturer's instructions or consult a professional to ensure correct pulley alignment.

- Avoid Excessive Force: Use caution and avoid applying excessive force when working with pulleys. Excessive force can lead to sudden movements, component damage, or personal injury. If a pulley or component is difficult to remove or install, reassess the procedure and seek guidance if necessary.

- Proper Lifting Techniques: When lifting heavy pulleys or components, use proper lifting techniques to avoid strain or injury. Lift with your legs, not your back, and ask for assistance if needed. Use lifting equipment or devices when appropriate to ensure safe handling of heavy pulleys.

- Follow Repair Procedures: Adhere to proper repair procedures outlined in the vehicle's repair manual or manufacturer's guidelines. Following correct procedures ensures safe and effective repair or maintenance work. If you are unsure about any step, consult an experienced professional or seek guidance from reliable sources.

Remember, safety should always be the top priority when working with car pulleys or any other automotive components. By following these safety considerations and exercising caution, you can minimize the risk of accidents, injuries, or damage to the vehicle or yourself.

What is the significance of proper alignment and tensioning in car pulley systems?

Proper alignment and tensioning are crucial factors in the functioning and reliability of car pulley systems. The alignment ensures that the pulleys are correctly positioned and oriented, while the tensioning ensures that the belts connecting the pulleys are appropriately tensioned. Here's a detailed explanation of the significance of proper alignment and tensioning in car pulley systems:

- Efficient Power Transmission: Proper alignment of the pulleys ensures that the belts maintain optimal contact with the pulley grooves. This allows for efficient power transmission from the engine to the driven components, such as the alternator, power steering pump, air conditioning compressor, and water pump. Misaligned pulleys can cause belt slippage, reducing power delivery and affecting the performance of these components.

- Prevention of Belt Wear and Damage: Correct alignment and tensioning help prevent excessive belt wear and damage. Misalignment can cause the belts to rub against the pulley edges or sides, leading to accelerated wear, fraying, or even belt failure. Improper tensioning can result in slippage, causing the belts to generate heat, wear unevenly, and potentially snap. Proper alignment and tensioning distribute the load evenly across the belts, minimizing wear and extending their lifespan.

- Reduced Noise and Vibration: Misaligned or improperly tensioned pulleys can result in increased noise and vibration. Misalignment causes the belts to oscillate or vibrate, generating noise and potentially creating an unpleasant driving experience. Proper alignment and tensioning reduce belt vibrations, resulting in smoother and quieter operation of the pulley system.

- Optimal Performance and Efficiency: Proper alignment and tensioning contribute to optimal performance and efficiency of the engine and the driven components. When the pulleys are aligned correctly, the belts operate at their designed angles, maximizing contact area and minimizing energy losses. This improves the overall efficiency of the system and ensures that the driven components receive the necessary power for optimal performance.

- Prevention of Component Damage: Misalignment and improper tensioning can place excessive stress on the pulleys and the driven components. This can lead to premature component failure, such as bearing damage, shaft wear, or seal leaks. Proper alignment and tensioning help distribute the loads evenly, reducing stress on the pulleys and components, and minimizing the risk of damage or failure.

- Enhanced Belt Life: Correct alignment and tensioning contribute to the longevity of the belts. When the pulleys are properly aligned, and the belts are adequately tensioned, the belts experience less stress, wear, and fatigue. This extends the lifespan of the belts, reducing the frequency of belt replacements and associated maintenance costs.

In conclusion, proper alignment and tensioning are essential for the reliable and efficient operation of car pulley systems. They ensure efficient power transmission, prevent belt wear and damage, reduce noise and vibration, optimize performance and efficiency, prevent component damage, and enhance the lifespan of the belts. Regular inspections and adjustments should be performed to maintain proper alignment and tensioning, ensuring the longevity and reliable functioning of the pulley system and its associated components.

What are the advantages of using high-quality pulleys in car engines?

Using high-quality pulleys in car engines offers several advantages that contribute to the overall performance, reliability, and efficiency of the vehicle. Here are the key benefits of using high-quality pulleys:

- Enhanced Durability: High-quality pulleys are built to withstand the demanding operating conditions within car engines. They are constructed using durable materials and undergo rigorous manufacturing processes, ensuring they can endure high temperatures, vibrations, and mechanical stresses. Improved durability reduces the likelihood of pulley failure, prolongs their lifespan, and minimizes the need for frequent replacements.

- Optimized Power Transmission: High-quality pulleys are designed to provide efficient power transmission from the engine to driven components. They have precise dimensions, well-engineered grooves, and optimal surface finishes that enable proper belt engagement and reduce slippage. Efficient power transmission ensures that the driven components receive the power they require, resulting in improved overall performance and functionality of the engine.

- Reduced Noise and Vibration: High-quality pulleys are carefully balanced and engineered to minimize noise and vibration. They undergo stringent quality control measures to ensure smooth operation and minimize unwanted vibrations that can cause noise and discomfort. Reduced noise and vibration contribute to a quieter and more comfortable driving experience.

- Improved Belt Life: High-quality pulleys help extend the life of belts connected to them. The precise design and smooth surfaces of these pulleys reduce friction and wear on the belts, resulting in increased belt longevity. By minimizing belt wear, high-quality pulleys reduce the risk of belt failure, improve reliability, and decrease maintenance costs associated with belt replacements.

- Precision and Accuracy: High-quality pulleys are manufactured to strict tolerances, ensuring precision and accuracy in their dimensions and performance. This precision helps maintain proper belt alignment, tension, and synchronization. Precise pulleys ensure that the belts operate optimally, preventing misalignment, slippage, or timing errors, which can negatively impact engine performance and potentially cause damage to components.

- Efficient System Operation: The use of high-quality pulleys promotes efficient operation of various engine systems and accessories. By providing reliable power transmission and proper belt engagement, these pulleys contribute to the effective functioning of systems such as the alternator, power steering, air conditioning, and water pump. Efficient system operation enhances overall vehicle performance, fuel efficiency, and driver satisfaction.

In summary, high-quality pulleys in car engines offer advantages such as enhanced durability, optimized power transmission, reduced noise and vibration, improved belt life, precision and accuracy, and efficient system operation. Investing in high-quality pulleys ensures the long-term reliability, performance, and efficiency of the engine and contributes to a smoother and more enjoyable driving experience.

editor by CX

2024-02-03