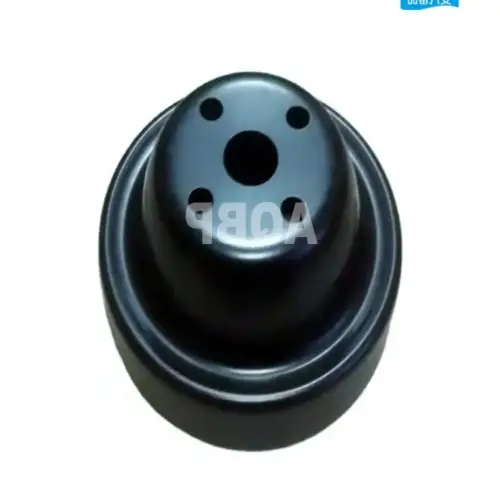

China Standard Car Sliding Door Parts Down Pulley Door Pulley for Hiace 68360-26130

The China Standard Car Sliding Door Parts Down Pulley Door Pulley for Hiace 68360-26130 is a high-quality auto part designed for sliding doors in cars. It is made with precision and durability in mind, ensuring smooth and reliable operation for your vehicle.

Product Description

Here are some key features of the China Standard Car Sliding Door Parts Down Pulley Door Pulley:

- 1. Price: EXW Price

- 2. Shipping Way: By Sea, DHL, UPS, FEDEX or as customers' requirements

- 3. Payment Terms: Via T/T, L/C, Paypal, Westerm Union, Moneygram

- 4. Delivery Time: Within 30 days after deposit or as customers' requirement

- 5. Packaging:

- 1. Carton Box

- 2. OEM Label

- 3. Neutral Package

- 4. We can perform according to customer's requirements

Our China Standard Car Sliding Door Parts Down Pulley Door Pulley is manufactured with the highest quality standards. We have a team of skilled professionals dedicated to ensuring the reliability and performance of our products. With our well-equipped facilities and strict quality control measures, we guarantee total customer satisfaction.

At our company, we not only provide the China Standard Car Sliding Door Parts Down Pulley Door Pulley, but also a wide range of other industrial products. Some of our main offerings include agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, roller chains, pulleys, planetary gearboxes, timing pulleys, bushings, and more. We take pride in offering high-quality products at competitive prices, along with excellent customer service. We also welcome customization requests for drawings and samples to meet your specific requirements.

Frequently Asked Questions (FAQs)

- Q: What is the material used for the China Standard Car Sliding Door Parts Down Pulley Door Pulley?

- A: The China Standard Car Sliding Door Parts Down Pulley Door Pulley is made with durable and high-quality materials to ensure long-lasting performance.

- Q: Can the China Standard Car Sliding Door Parts Down Pulley Door Pulley be used in other car models?

- A: While this pulley is specifically designed for Hiace 68360-26130, it may also be compatible with other car models. We recommend consulting with our experts for further information.

- Q: Are OEM labels available for the China Standard Car Sliding Door Parts Down Pulley Door Pulley?

- A: Yes, we offer OEM labels as part of our packaging options for the convenience of our customers.

- Q: How can I place an order for the China Standard Car Sliding Door Parts Down Pulley Door Pulley?

- A: To place an order, please contact us through the provided contact information. Our team will assist you with the ordering process and answer any further questions you may have.

- Q: Can I customize the China Standard Car Sliding Door Parts Down Pulley Door Pulley?

- A: Yes, we welcome customization requests for drawings and samples. Our team will work closely with you to meet your specific requirements.

All the content of this page is from the Internet, the content is only as a reference for product selection. Our products are replacement parts and not original spare parts. We are not the holder of the original trademarks of the content. Our products are only suitable for after-sales replacement parts and not original spare parts. Our replacement parts can be perfectly adapted to the original spare parts. If you need to buy original spare parts, please contact the original factory to buy. If you want to buy original spare parts, please contact the original supplier for purchase.

Performance Characteristics of Car Pulley

Car pulleys are essential components in a vehicle's engine system. They serve various purposes and offer several performance characteristics that contribute to the overall efficiency of the system.

1. High Durability: Car pulleys are designed to withstand the demanding conditions of engine operation, ensuring long-lasting performance.

2. Smooth Operation: These pulleys are precisely engineered to minimize friction and vibrations, resulting in smooth and efficient power transmission.

3. Noise Reduction: Car pulleys are designed to minimize noise during operation, providing a quieter driving experience.

4. Enhanced Efficiency: By optimizing power transmission, car pulleys help increase the overall efficiency of the engine system, leading to improved fuel economy.

Types and Characteristics of Car Pulley

There are various types of car pulleys, each with its own unique characteristics.

1. Belt-Driven Pulleys: These pulleys are commonly used in accessory systems such as the alternator, power steering, and air conditioning. They are known for their smooth operation and reliable performance.

2. Timing Belt Pulleys: These pulleys are crucial in the engine's timing system, ensuring precise synchronization between the crankshaft and camshaft. They are designed to withstand high temperatures and provide accurate timing.

3. Serpentine Belt Pulleys: Found in modern vehicles, serpentine belt pulleys are responsible for driving multiple accessories simultaneously. They offer efficient power transmission and improved space utilization.

Advantages of Different Materials for Car Pulley

Car pulleys can be made from various materials, each offering its own set of advantages.

1. Aluminum Pulleys: Lightweight and corrosion-resistant, aluminum pulleys reduce the overall weight of the engine system, resulting in improved fuel efficiency.

2. Steel Pulleys: Known for their high strength and durability, steel pulleys are commonly used in heavy-duty applications where reliability is crucial.

3. Composite Pulleys: These pulleys combine the benefits of different materials, offering a balance between strength, weight, and cost. They are often used in modern vehicles for their versatility.

Application of Car Pulley in Various Systems

Car pulleys play a vital role in various systems within a vehicle. Their application extends beyond just the engine system, as they are utilized in several other areas:

1. Engine Systems: Car pulleys are crucial components in the engine's timing system, ensuring precise synchronization and optimal performance.

2. Accessory Systems: Pulleys are used in accessory systems such as power steering, air conditioning, and alternators, providing power to these components for smooth operation.

3. Transmission Systems: Car pulleys are utilized in transmission systems to facilitate smooth gear shifting and efficient power transmission.

4. Fuel Systems: Certain types of pulleys are used in fuel systems, ensuring proper delivery of fuel to the engine for optimal combustion.

5. Auxiliary Systems: Car pulleys are also employed in auxiliary systems such as water pumps and superchargers, contributing to their efficient operation.

Future Development Trends and Opportunities

The car pulley industry is constantly evolving, and there are several future development trends and opportunities to consider.

1. Lightweight Materials: With the increasing demand for fuel efficiency, the use of lightweight materials in car pulleys is expected to grow, resulting in improved overall performance.

2. Advanced Manufacturing Techniques: The adoption of advanced manufacturing techniques, such as 3D printing, can enhance the precision and efficiency of car pulley production.

3. Electric Vehicle Integration: As electric vehicles gain popularity, there will be opportunities to develop specialized pulleys for electric drivetrains, optimizing their performance and efficiency.

4. Smart Pulley Systems: The integration of sensors and intelligent control systems into car pulleys can enable real-time monitoring and adjustment, further optimizing performance and minimizing maintenance.

How to Choose a Suitable Car Pulley

Choosing the right car pulley is essential to ensure optimal performance and longevity. Consider the following aspects when selecting a suitable pulley:

1. Load Capacity: Determine the maximum load the pulley will need to withstand to ensure it can handle the demands of the specific application.

2. Material: Select a pulley material that suits the application's requirements, considering factors such as durability, weight, and corrosion resistance.

3. Diameter and Size: Choose a pulley with the appropriate diameter and size to ensure proper fit and compatibility with other components.

4. Type of Pulley: Consider the specific type of pulley required for the system, such as a timing belt pulley or serpentine belt pulley, based on the vehicle's specifications.

5. Bore Size: Ensure that the pulley's bore size matches the shaft diameter to ensure secure and accurate installation.

Summary

Car pulleys are integral components in a vehicle's engine and various systems. They offer performance characteristics such as durability, smooth operation, noise reduction, and enhanced efficiency. Different types of pulleys, made from materials like aluminum, steel, and composites, have their own advantages. Car pulleys find applications in engine systems, accessory systems, transmission systems, fuel systems, and auxiliary systems, showcasing their value and importance. The future of car pulleys lies in lightweight materials, advanced manufacturing techniques, electric vehicle integration, and smart pulley systems. When selecting a suitable car pulley, consider factors such as load capacity, material, diameter and size, type of pulley, and bore size. Choose wisely to ensure optimal performance and compatibility.

Author: Dream