Product Description

Product Specification:

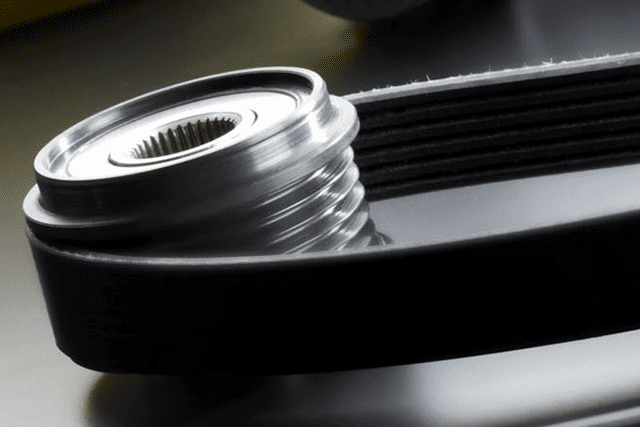

Auto Parts/Auto AC Clutch Pulley/Auto AC Compressor Clutch Part

| Item No.: | 8571176 |

| Diameter: | D123/119 |

| Belt Groove Type: | 6-PK |

| Assembly hole: | 60/97 |

| Total Height:: | 33 |

| Aligment: | 16.9 |

| Bearing: | 35×55×20 |

| Application: | |

| Packaging: | Carton with pallet packing |

| Delivery: | 30 days |

Product Description

Detailed description of AC Clutch Pulley for HYUNDAI

1. Material: Iron

2. Application: AC Clutch Pulley for HYUNDAI

3. Good quality with reasonable price.

4. Payment: T/T or Western Union.

30% advance by T/T before producing and 70% balance by T/T before shipment.

5. Delivery time: 3-5 days for sample;30-35 days for mass production.

6. Package: Standard exporting carton with pallet packing

7. MOQ: 100pcs

Our Services

After sale service:

We are eager to get the advice from our customers to make our products more perfect to use, also we can help them to analyze and solve the after-sale's problem and provide the settlement for the trouble timely to enhance our customers sales quantity.

FAQ

Q: What is the minimum order quantity? (MOQ)

A: Normally 100pcs/item. Trial orders and further requests can be negotiated.

Q: Can I order 1 sample?

A: Sure. Sample is provided by reasonable charges.

Q:What is the delivery time?

A: Maximum 30-35days after receiving the relevant payment, samples is 1-7working days around

Q:What is the payment terms?

A:30% by TT as deposit, the balance 70% before shipment for new customer.

Q: Can we do OEM brand?

A: Yes. OEM is available for brands and packages.

Q:If I want to visit your company and factory, which is the nearest airport?

A: It is HuangYan Airport. About 1 hours car drive from HuangYan to our factory. HangZhou airport is also available which is about 2 and a half hours car to our factory.

Q: Can you help book the hotel?

A:If you need any assistance, just contact us, and we are your trusted friends in China.

Contact:

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | 1 Year |

|---|---|

| Warranty: | 1 Year |

| Part: | Clutch Plates |

| Samples: |

US$ 15/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What safety considerations should be kept in mind when working with car pulleys?

Working with car pulleys involves potential hazards, and it's crucial to prioritize safety to prevent accidents or injuries. Here are some important safety considerations to keep in mind when working with car pulleys:

- Personal Protective Equipment (PPE): Always wear appropriate personal protective equipment, such as safety glasses/goggles, gloves, and protective clothing. PPE helps protect against potential hazards like flying debris, sharp edges, or chemical exposures. Ensure that your PPE is in good condition and fits properly.

- Engine Shutdown and Cooling: Before working with car pulleys, ensure that the engine is shut off and has had sufficient time to cool down. Hot engine components, including pulleys, can cause burns or other injuries. Allow the engine to cool to a safe temperature before carrying out any maintenance or repair work.

- Secure the Vehicle: Park the vehicle on a level surface and engage the parking brake to prevent any unintended movement. If necessary, use wheel chocks to further secure the vehicle and prevent rolling. Working on a stable and stationary vehicle minimizes the risk of accidents or injuries caused by unexpected vehicle movement.

- Disconnect the Battery: When working with pulleys connected to the electrical system, such as alternator pulleys, it's advisable to disconnect the vehicle's battery. This precaution helps prevent electrical shocks or short circuits. Refer to the vehicle's manual for specific instructions on disconnecting the battery safely.

- Use Proper Tools and Equipment: Ensure that you have the appropriate tools and equipment for the task at hand. Using improper tools or makeshift solutions can lead to accidents or damage to the pulley system. Follow the manufacturer's recommendations and instructions when using tools and equipment.

- Pulley Tension Release: If you need to release tension from a pulley, such as when removing a belt, follow the manufacturer's guidelines or repair manual instructions. Improperly releasing tension can cause sudden movements or accidents. Use the appropriate tools or techniques to release tension safely.

- Pulley Alignment: When installing or replacing pulleys, ensure proper alignment with other components, such as belts, accessories, or pulley grooves. Misaligned pulleys can cause belt slippage, improper power transmission, or premature component wear. Follow the manufacturer's instructions or consult a professional to ensure correct pulley alignment.

- Avoid Excessive Force: Use caution and avoid applying excessive force when working with pulleys. Excessive force can lead to sudden movements, component damage, or personal injury. If a pulley or component is difficult to remove or install, reassess the procedure and seek guidance if necessary.

- Proper Lifting Techniques: When lifting heavy pulleys or components, use proper lifting techniques to avoid strain or injury. Lift with your legs, not your back, and ask for assistance if needed. Use lifting equipment or devices when appropriate to ensure safe handling of heavy pulleys.

- Follow Repair Procedures: Adhere to proper repair procedures outlined in the vehicle's repair manual or manufacturer's guidelines. Following correct procedures ensures safe and effective repair or maintenance work. If you are unsure about any step, consult an experienced professional or seek guidance from reliable sources.

Remember, safety should always be the top priority when working with car pulleys or any other automotive components. By following these safety considerations and exercising caution, you can minimize the risk of accidents, injuries, or damage to the vehicle or yourself.

What maintenance procedures are necessary to ensure the reliability of car pulleys?

Maintaining the reliability of car pulleys is crucial for the proper functioning of the engine and its driven components. Regular maintenance procedures help prevent premature wear, belt slippage, and potential component failures. Here's a detailed explanation of the maintenance procedures necessary to ensure the reliability of car pulleys:

- Inspecting for Damage: Regular visual inspections are essential to identify any signs of damage or wear on the pulleys. Look for cracks, chips, excessive wear, or any deformation in the pulley structure. Damaged pulleys should be replaced promptly to prevent further issues and potential belt failure.

- Checking Belt Tension: Proper belt tension is crucial for reliable power transmission and to prevent slippage. Use a tension gauge or follow the manufacturer's specifications to check the tension of the belts connected to the pulleys. Adjust the tension as necessary to maintain the recommended tension range. Over-tensioning can strain the pulleys and accessories, while under-tensioning can cause belt slippage and reduced power delivery.

- Inspecting Belt Condition: Inspect the condition of the belts for signs of wear, fraying, cracking, or glazing. Damaged or worn belts should be replaced promptly to ensure reliable operation. Additionally, check for proper belt alignment and make sure the belts are properly seated in the pulley grooves to prevent slippage and premature wear.

- Lubrication: Some pulleys may require lubrication, especially those with bearing mechanisms. Consult the vehicle's manual or manufacturer's recommendations to determine if lubrication is necessary and the appropriate lubricant to use. Proper lubrication helps reduce friction, minimize wear, and maintain smooth pulley operation.

- Checking for Misalignment: Pulley misalignment can lead to belt tracking issues, increased wear, and reduced performance. Regularly check the alignment of the pulleys to ensure they are properly aligned along the same plane. Misaligned pulleys should be adjusted or realigned to prevent belt misalignment and associated problems.

- Inspecting Pulley Mounting: Check the pulley mounting surfaces and bolts for any signs of damage, corrosion, or looseness. Ensure that the pulleys are securely mounted and that the bolts are tightened to the specified torque. Loose or damaged mounting can lead to pulley wobbling, misalignment, and potential component damage.

- Regular Maintenance Schedule: Follow the manufacturer's recommended maintenance schedule for your specific vehicle. This may include periodic inspections, belt replacements, and other maintenance tasks related to the pulleys and driven components. Adhering to the recommended maintenance intervals helps ensure the longevity and reliability of the pulleys.

In conclusion, ensuring the reliability of car pulleys requires regular maintenance procedures. This includes inspecting for damage, checking belt tension and condition, proper lubrication (if applicable), inspecting for misalignment, checking pulley mounting, and following a regular maintenance schedule. By performing these maintenance procedures, you can detect and address issues early, prevent premature wear and failures, and maintain the reliable operation of the pulleys and the overall engine system.

What is a car pulley, and how is it used in automotive systems?

A car pulley is a mechanical component used in automotive systems to transfer power, drive auxiliary components, and facilitate the operation of various systems within a vehicle. It is a wheel-like device with a grooved rim that is typically made of metal or composite materials. Here's a detailed explanation of the car pulley and its applications in automotive systems:

A car pulley operates based on the principles of rotational motion. It is usually mounted on the engine crankshaft, which is connected to the pistons and converts the reciprocating motion of the pistons into rotational motion. The pulley is driven by the rotational motion of the crankshaft and is connected to other components or systems through belts or chains.

There are different types of car pulleys used in automotive systems, including:

- Accessory Pulleys: These pulleys are responsible for driving various accessory components in the vehicle, such as the alternator, power steering pump, water pump, and air conditioning compressor. The accessory pulleys are typically connected to these components through belts, such as the serpentine belt or V-belts, and transfer power from the engine to operate these systems.

- Tensioner Pulleys: Tensioner pulleys are used to maintain the proper tension of belts in the automotive system. They are designed to apply tension to the belts, ensuring that they remain properly seated on the pulleys and operate smoothly. Tensioner pulleys often have built-in mechanisms, such as springs or hydraulic systems, to automatically adjust the tension and compensate for belt stretch or wear.

- Idler Pulleys: Idler pulleys are used to change the direction of a belt or provide additional support and tension to the belt. They are stationary pulleys that guide the belt around various components and help maintain proper belt alignment. Idler pulleys play a crucial role in ensuring smooth belt operation and preventing slippage or excessive wear.

- Crankshaft Pulley: The crankshaft pulley is directly attached to the crankshaft and is responsible for driving the other pulleys and components in the accessory drive system. It is often a larger pulley compared to the accessory pulleys and serves as the starting point for power transfer through belts or chains.

In automotive systems, car pulleys are used to transmit power efficiently and reliably from the engine to various components and systems. They enable the operation of critical systems such as the electrical charging system (alternator), power steering system (power steering pump), cooling system (water pump), and air conditioning system (air conditioning compressor).

The rotation of the car pulleys is synchronized with the engine speed, allowing the driven components to operate at the appropriate speed and deliver the required performance. Proper belt tension, guided by tensioner and idler pulleys, ensures efficient power transfer and prevents belt slippage or excessive wear. Additionally, car pulleys are designed to handle the high temperatures and demanding conditions of the engine compartment.

Overall, car pulleys are essential components in automotive systems, enabling the efficient and reliable operation of auxiliary systems and ensuring the smooth functioning of a vehicle's various functions.

editor by CX

2024-03-11