Product Description

|

Our Package :

Packing & Delivery (Show As Above):

Inner Packing →Strong & waterproof plastic big is packed inside, to keep the product in safe condition.

Or as customer requests.

Outer Packing →Multilayer wooden box with strong bandages, used for standard export package.

Or customized as per customer's requirements.

Our Company

ZheJiang CHINAMFG Machinery Manufacture Co., Ltd.

--Branch of CHINAMFG Industry Ltd.

We specialize in Metal Parts Solution for Vehicle, Agriculture machine, Construction Machine, transportation equipment, Valve and Pump system etc.

With keeping manufacturing process design, quality plHangZhou, key manufacturing processes and final quality control in house.

We are mastering key competence to supply quality mechanical parts and assembly to our customers for both Chinese and Export Market .

To satisfy different mechanical and functional requirements from our customers we are making a big range of metal products for our clients on base of different blanks solutions and technologies.

These blanks solutions and technologies include processes of Iron Casting, Steel Casting, Stainless Steel Casting, Aluminum Casting and Forging.

During the early involvement of the customer's design process, we are giving professional input to our customers in terms of process feasibility, cost reduction and function approach.

You are welcome to contact us for technical enquiry and business cooperation.

FAQ:

1. Are you a manufacturer or a trading company?

We are a professional manufacturer with over 15 years' export experience for designing and producing vehicle machinery parts.

2. How can I get some samples?

If you need, we are glad to offer you samples for free, but the new clients are expected to pay the courier cost,

and the charge will be deducted from the payment for formal order.

3. Can you make casting according to our drawing?

Yes, we can make casting according to your drawing, 2D drawing, or 3D cad model. If the 3D cad model can be supplied,

the development of the tooling can be more efficient. But without 3D, based on 2D drawing we can still make the samples properly approved.

4. Can you make casting based on our samples?

Yes, we can make measurement based on your samples to make drawings for tooling making.

5. What's your quality control device in house?

We have spectrometer in house to monitor the chemical property, tensile test machine to control the mechanical property and UT Sonic as NDT checking method to control the casting detect under the surface of casting.

| Die Casting Machine Type: | Hot Chamber Die Casting Machine |

|---|---|

| Die Casting Method: | Precision Die Casting |

| Application: | Auto Parts |

| Machining: | CNC Machining |

| Material: | Aluminum |

| Surface Preparation: | Anodize, Painting |

| Samples: |

US$ 4.45/KG

1 KG(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

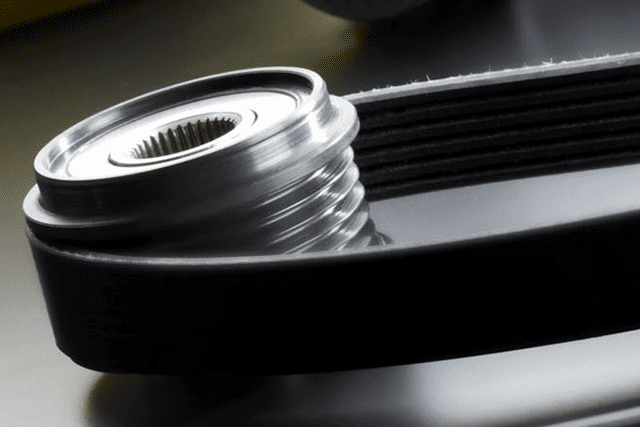

Are there different types of car pulleys, and how do they vary in applications?

Yes, there are different types of car pulleys, and they vary in applications based on their design, function, and the components they are connected to. Here's a detailed explanation of the different types of car pulleys and their varying applications:

- Idler Pulleys: Idler pulleys are stationary pulleys that guide and route the belt in a specific path. They are designed to maintain tension in the belt and ensure proper alignment between the driving and driven pulleys. Idler pulleys are commonly used in serpentine belt systems to guide the belt around various accessories, such as the alternator, power steering pump, and air conditioning compressor.

- Tensioner Pulleys: Tensioner pulleys are similar to idler pulleys but include a built-in mechanism to automatically maintain proper belt tension. They are commonly used in serpentine belt systems to provide constant tension on the belt, compensating for belt stretch and wear. Tensioner pulleys help prevent belt slippage, ensure efficient power transmission, and reduce the need for manual belt adjustments.

- Crankshaft Pulleys: Crankshaft pulleys are connected to the engine's crankshaft and are responsible for transmitting power from the engine to various accessories or components. They are usually larger in size and serve as the main driving pulleys in the engine's accessory drive system. Crankshaft pulleys are typically connected to the alternator, power steering pump, air conditioning compressor, and water pump.

- Supercharger Pulleys: Supercharger pulleys are specific to vehicles equipped with supercharger systems. These pulleys are connected to the supercharger and help drive it to compress the incoming air, resulting in increased engine performance. Supercharger pulleys come in different sizes or diameters, allowing for adjustments to the supercharger's speed and boost levels, which directly influences engine power output.

- Turbocharger Pulleys: Turbocharger pulleys are specific to vehicles equipped with turbocharger systems. Similar to supercharger pulleys, they are connected to the turbocharger and drive its turbine wheel using exhaust gases. Turbocharger pulleys, often referred to as turbine housings, come in various sizes and designs to optimize turbocharger spooling characteristics, boost levels, and overall performance.

- Accessory Pulleys: Accessory pulleys are connected to individual accessories in the engine's accessory drive system, such as the alternator, power steering pump, air conditioning compressor, and water pump. They transmit power from the crankshaft pulley to these components, allowing them to operate and perform their respective functions. Accessory pulleys may have different sizes, groove configurations, or designs based on the specific accessory they are driving.

The varying types of car pulleys mentioned above have specific applications within the vehicle's engine system. Idler pulleys and tensioner pulleys help guide and maintain proper tension in the belts, ensuring efficient power transmission. Crankshaft pulleys serve as the main driving pulleys, connecting the crankshaft to the engine's accessories. Supercharger and turbocharger pulleys are specific to forced induction systems, boosting engine performance. Accessory pulleys are connected to individual accessories, allowing them to operate and perform their intended functions.

It's important to note that the specific types and applications of car pulleys may vary depending on the vehicle make, model, and engine configuration. Manufacturers design and select pulleys based on the specific requirements and characteristics of the engine system.

How do car pulleys contribute to the overall fuel efficiency of a vehicle?

Car pulleys play a significant role in the overall fuel efficiency of a vehicle. They contribute to the efficient operation of various engine-driven components and help reduce parasitic losses. Here's a detailed explanation of how car pulleys contribute to the overall fuel efficiency of a vehicle:

- Reduced Parasitic Drag: Car pulleys are responsible for driving accessories such as the alternator, power steering pump, air conditioning compressor, and water pump. These accessories draw power from the engine, creating parasitic drag that consumes fuel. Efficiently designed and properly tensioned pulleys minimize the resistance encountered by these accessories, reducing the amount of power required to operate them and minimizing fuel consumption.

- Optimized Power Delivery: Pulleys help optimize power delivery to the driven components. Properly sized and aligned pulleys ensure that the engine's power is efficiently transferred to the accessories without unnecessary energy losses. This allows the accessories to operate at their intended speeds and power requirements, minimizing the need for additional energy and improving overall fuel efficiency.

- Improved Throttle Response: Car pulleys can enhance throttle response, which indirectly affects fuel efficiency. Lighter pulleys with reduced rotational inertia can reduce the time it takes for the engine to respond to throttle inputs. This improved response allows for more precise control over the engine's power output, enabling drivers to modulate their acceleration and maintain efficient fuel consumption during various driving conditions.

- Efficient Cooling System Operation: The water pump, driven by a pulley, circulates coolant throughout the engine to maintain optimal operating temperatures. Properly functioning pulleys ensure that the water pump operates at the appropriate speed, delivering sufficient coolant flow for efficient engine cooling. This prevents overheating and the need for fuel-consuming measures, such as running the cooling fans at higher speeds, to maintain engine temperature.

- Optimal Charging System Performance: The alternator, driven by a pulley, is responsible for charging the vehicle's battery and providing electrical power to various electrical systems. Well-maintained pulleys ensure that the alternator operates at the correct speed, generating the necessary electrical power without excessive strain on the engine. This helps maintain the battery's charge, reducing the need for frequent recharging and optimizing fuel efficiency.

- Proper Power Steering Function: The power steering pump, driven by a pulley, assists in steering effort by providing hydraulic power. Smooth and efficient operation of the power steering system reduces the strain on the engine and minimizes fuel consumption. Well-maintained pulleys ensure that the power steering pump operates optimally, supporting efficient power assistance and reducing unnecessary power draw from the engine.

In summary, car pulleys contribute to the overall fuel efficiency of a vehicle by reducing parasitic drag, optimizing power delivery, improving throttle response, facilitating efficient cooling system operation, enabling optimal charging system performance, and supporting proper power steering function. Proper maintenance, alignment, and tensioning of pulleys are essential to ensure their efficient operation, minimize energy losses, and maximize fuel efficiency.

How does the size and design of a car pulley impact engine performance?

The size and design of a car pulley have a significant impact on engine performance. The pulley's size and design influence critical factors such as power output, torque characteristics, component speeds, and efficiency. Here's a detailed explanation of how the size and design of a car pulley impact engine performance:

- Power Output: The size of the pulley directly affects the power output of the engine. A larger pulley on the crankshaft will result in a slower rotational speed, reducing the power output. Conversely, a smaller pulley will increase the rotational speed and potentially boost power output. Modifying the size of the pulley can be used to fine-tune the engine's power delivery characteristics and optimize performance for specific applications.

- Torque Characteristics: The size and design of the pulley impact the torque characteristics of the engine. A smaller pulley can increase the torque at lower engine speeds, providing better low-end responsiveness and acceleration. On the other hand, a larger pulley can improve top-end torque, allowing for higher speeds. The choice of pulley size and design should consider the desired torque curve and the engine's intended use.

- Component Speeds: The size and design of pulleys affect the rotational speeds of various engine components. For example, the size of the crankshaft pulley determines the speeds at which the driven components, such as the alternator, water pump, and power steering pump, operate. Proper sizing and design ensure that the components operate within their optimal speed ranges, maximizing their efficiency and performance.

- Belt Tension and Slippage: The size and design of the pulley influence the tension and potential slippage of the belts connected to it. A properly sized pulley ensures the correct tension in the belts, preventing excessive slippage that can lead to power loss and reduced efficiency. The pulley's design, including the shape and depth of the grooves, also plays a role in maintaining proper belt engagement and minimizing slippage.

- Efficiency: The size and design of the pulley impact the overall efficiency of the engine. An appropriately sized pulley helps optimize power transmission, minimizing energy losses due to belt slippage or excessive friction. Additionally, pulleys with well-designed grooves and smooth surfaces reduce friction, improving overall efficiency by reducing energy wastage and enhancing the engine's ability to convert fuel into useful work.

- Accessory Operation: The size and design of pulleys influence the operation of engine accessories. Properly sized pulleys ensure that the accessories, such as the alternator, power steering pump, and air conditioning compressor, operate at the correct speeds to provide optimal performance. A mismatch between pulley size and accessory requirements can lead to underperformance or excessive load on the engine.

In conclusion, the size and design of a car pulley have a significant impact on engine performance. They affect power output, torque characteristics, component speeds, belt tension, efficiency, and accessory operation. Careful consideration of pulley size and design is crucial in optimizing engine performance for specific requirements, balancing power, torque, and efficiency to achieve the desired performance characteristics.

editor by CX

2023-12-01