Product Description

| Product Description | |

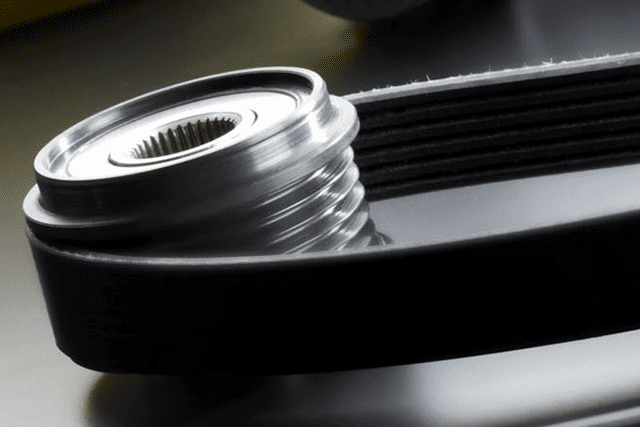

| Products name : | OEM service customized CNC turning milling aluminum pulley.OEM/ODM Aluminum 6061/7075 machined turning pulley wheels for racing car |

| Material : | Aluminum alloy 6061. 6063. 7075 .5082 and etc . steel alloy /stainless steel 304/316L , titanium Gr2/Gr5 , brass/ copper , plastics and so on |

| Surface treatment : | painting , coating , oxide , anodized , powder coating , or according customer require |

| MOQ : | 10pcs |

| samples : | first will do samples send to customer test , after confirmed quality is ok , then do production |

| Package : | each parts will use foam pack , outer is wood box or pallet , strong package guarantee products no any damage ,injured during transportaion way. |

| Services : | customized , OEM/ODM service . machining service |

| Application : | automotive spare parts , motorcycle parts , machine , electronic spare parts etc |

| Market : | North American , european, middle east, african , Canada, Englad and so on |

Products show :

Package :

Our company :

Certificate :

About Us :

Integrated precision CNC machining solutions supplier

As an OEM /ODM manufacturer ,quality and service are our hallmark . Especially your project

Requires high accurate and surface treatment .

Our services is capable of handling larger quantity custom components in a range of

CNC machining. Milling ,turning ,die-casting ,sheet metal stamping etc

These CNC deep processing products active in automotive ,telecommunication devices,

electronic, industrial machinery , medical, aerospace ........

We are always customers trustworthy and reliable partner and supported

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 10-15 days . or it is 15-20 days if the

quantity is larger

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of

express shipping fee

Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in

advance ,balance before shippment.

If you have another question, pls feel free to contact us as below:

Contact Information :

web:HangZhouderf

pls contact us freely

OEM Customized CNC lathe aluminum motorcycle parts

OEM service customized CNC turning milling aluminum pulley

OEM/ODM Aluminum 6061/7075 machined turning pulley wheels for racing car

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Yes |

|---|---|

| Warranty: | 12 Months |

| Condition: | New |

| Samples: |

US$ 5/Piece

1 Piece(Min.Order) | Order Sample 100% according clients drawings do it

|

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do you select the right car pulley for a specific automotive repair or upgrade?

Selecting the right car pulley for a specific automotive repair or upgrade requires careful consideration of various factors. Here's a detailed explanation of the steps involved in selecting the right car pulley:

- Identify the Specific Requirement: Determine the purpose of the car pulley. Are you replacing a faulty pulley, upgrading for improved performance, or modifying the engine system? Identifying the specific requirement helps narrow down the options and select the appropriate type of pulley.

- Refer to the Vehicle's Specifications: Consult the vehicle's specifications, such as the owner's manual or manufacturer's guidelines, to gather information about the original equipment pulley specifications. This includes details like the pulley's diameter, width, groove configuration, and other specific requirements. Matching these specifications ensures compatibility and proper fitment.

- Research and Compatibility: Conduct thorough research to identify aftermarket pulleys or upgrades available for your vehicle. Look for reputable manufacturers or suppliers that offer pulleys specifically designed for your vehicle make, model, and engine configuration. Check for compatibility with your engine system, accessory drive setup, and any other relevant considerations.

- Consider Performance and Design: If you are upgrading or modifying the engine system, consider performance-oriented pulleys that can enhance power delivery, reduce rotational inertia, or improve efficiency. Look for lightweight materials, optimized designs, or adjustable pulleys that allow customization based on your specific needs.

- Consult with Experts: Seek advice from automotive professionals, such as mechanics or performance specialists, who have expertise in car pulleys. They can provide insights, recommendations, and guidance based on their experience and knowledge. They may suggest specific brands, models, or configurations that are suitable for your intended use.

- Quality and Reliability: Prioritize pulleys that are manufactured by reputable brands known for their quality and reliability. Read customer reviews, assess the manufacturer's reputation, and consider factors like warranty coverage and product support. Choosing a high-quality pulley ensures durability, longevity, and optimal performance.

It's important to note that the selection process may vary depending on the specific automotive repair or upgrade. For routine replacements, it is generally recommended to use OEM-equivalent pulleys to maintain compatibility and performance. However, for performance upgrades or modifications, aftermarket pulleys designed for specific applications may be more suitable.

Ultimately, selecting the right car pulley requires a combination of research, consideration of the vehicle's specifications, compatibility with the engine system, performance requirements, and expert advice. Taking the time to make an informed decision ensures that you choose the appropriate pulley for your automotive repair or upgrade, leading to reliable and efficient operation.

What role do car pulleys play in controlling and synchronizing engine components?

Car pulleys play a crucial role in controlling and synchronizing engine components, ensuring their proper operation and coordination. They are responsible for transmitting power from the engine's crankshaft to various driven components and systems. Here's an in-depth explanation of the role car pulleys play in controlling and synchronizing engine components:

- Power Transmission: Car pulleys, in conjunction with belts or chains, transmit rotational power from the engine's crankshaft to driven components and systems. The pulleys are connected to the crankshaft and rotate as the engine runs. As the crankshaft pulley turns, it drives the belts or chains that are connected to other pulleys located on components such as the alternator, power steering pump, air conditioning compressor, water pump, and more. This power transmission enables these components to function and perform their respective tasks.

- Belt Routing: Car pulleys play a critical role in determining the routing of belts throughout the engine. The pulley locations and orientations are carefully designed to ensure the most efficient and appropriate path for the belts to wrap around. Proper belt routing enables the pulleys to drive the desired components without interference, minimizing the risk of belt slippage, misalignment, or contact with other engine parts.

- Tension Control: Car pulleys contribute to controlling the tension in belts or chains. Tension is crucial to ensure proper power transmission and prevent slippage. Some pulleys incorporate tensioner mechanisms that automatically adjust the tension in the belts to compensate for wear and stretch over time. These tensioners help maintain optimal belt tension, ensuring reliable power delivery to the driven components.

- Timing and Synchronization: In engines with overhead camshafts (OHC), car pulleys play a vital role in controlling the timing and synchronization of valve operation. The pulleys are connected to the camshafts, which open and close the engine's valves. The timing and synchronization of valve operation are critical for proper combustion and engine performance. Timing pulleys, often toothed or geared, ensure precise timing and synchronization between the crankshaft and camshaft(s), enabling efficient intake and exhaust valve operation.

- Accessory Operation: Car pulleys facilitate the operation of various engine accessories. The pulleys connected to components like the alternator, power steering pump, and air conditioning compressor enable these accessories to receive power and perform their functions. By controlling the rotational speed and power delivery, the pulleys ensure that the accessories operate at the required speeds and provide the necessary power for optimal performance.

- Harmonic Balancing: Some car pulleys, particularly the crankshaft pulley, incorporate harmonic balancers or dampers. These components help reduce vibrations and torsional forces generated by the engine's reciprocating motion. The harmonic balancer absorbs and dissipates these vibrations, protecting the engine and its components from excessive wear and potential damage.

In summary, car pulleys play a vital role in controlling and synchronizing engine components. They facilitate power transmission, control belt routing, adjust belt tension, ensure timing and synchronization of valve operation, enable accessory operation, and contribute to harmonic balancing. Properly designed and maintained pulleys are essential for the reliable and efficient operation of engine components, ensuring smooth coordination and optimal performance of the engine as a whole.

How do car pulleys contribute to the proper functioning of the engine?

Car pulleys play a crucial role in ensuring the proper functioning of the engine. Their contribution is vital for power transmission, belt guidance, load adaptation, and accessory operation. Here's a detailed explanation of how car pulleys contribute to the engine's proper functioning:

- Power Transmission: Car pulleys are integral for power transmission within the engine. The crankshaft pulley, connected directly to the engine's crankshaft, serves as the starting point for power transfer. As the engine rotates, the crankshaft pulley rotates, transmitting power to other components and systems through belts or chains. This power transmission enables the engine to drive various systems, such as the alternator, water pump, power steering pump, and air conditioning compressor.

- Belt Guidance: Pulleys provide guidance for belts within the engine. The grooved rim on the pulleys serves as a track for the belts, ensuring they remain properly seated and aligned during operation. By guiding the belts, pulleys prevent slippage and ensure efficient power transfer. Proper belt guidance is essential for maintaining the synchronization between the engine's crankshaft and driven components, such as the camshaft(s) in an overhead camshaft engine.

- Load Adaptation: Car pulleys allow for load adaptation within the engine. Load adaptation refers to the adjustment of the effective diameter or speed ratio of pulleys to optimize power delivery based on the engine's operating conditions. Variable pulleys or movable flanges can be used to adjust the position of belts or chains, enabling the engine to adapt to varying load demands. Load adaptation ensures that the engine operates efficiently and delivers the required power for different driving situations and loads.

- Accessory Operation: Car pulleys are essential for the operation of various engine accessories. The engine's accessory pulleys, driven by the crankshaft, transmit power to components such as the alternator, power steering pump, air conditioning compressor, and water pump. These accessories are vital for electrical generation, power steering assistance, air conditioning, and coolant circulation, respectively. The pulleys ensure that the accessories operate synchronously with the engine, enabling their proper functioning.

Overall, car pulleys contribute significantly to the proper functioning of the engine by facilitating power transmission, guiding belts, adapting to load conditions, and enabling the operation of essential accessories. Their role ensures that the engine operates efficiently, delivers power to various systems, and functions reliably under different driving conditions.

editor by CX

2024-05-06