Product Description

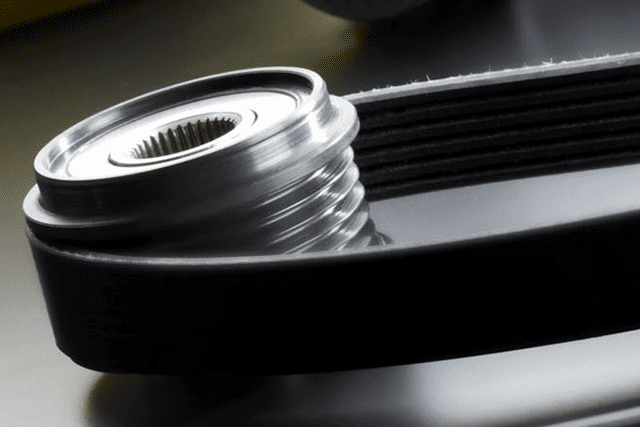

Name:China Benz Car Cooling System Air Conditioning Cylinder Compressor Clutch Pulley

1) inquiry will be replied in 24 hours 2) cheap price 3) free sample 4)Low MOQ

ACE have gain expertise in providing Precision Machinery Job Works that are widely used in many industries to add new life to the machines. These job works are executed by our experienced professionals making optimum utilization of modern tools and equipment. Our innovative approaches to lend new life to old machines enabled us to gain a remarkable position in industry. Customers can avail these job work from us as per their needs.

Our company is recognized by features of "Precise Finish, Accurate Dimensions, Abrasion & Corrosion Resistance,Robustness."

We hope to cooperate with you and develop together!

Works Ace Machining Can Do Of CNC Machining

| Works We Can Do | CNC Lathing | CNC Milling | Custom Machining Works | OEM Machining Works |

| Materials We Can Do | Steel | Aluminum | Copper | Other Metal |

| Finish We Can Do | Polishing | Brass | Anodizing | Plating etc. |

You Will Get:

* Competitive Price Of CNC Precision Machinery part

* Good Quality Assurance

* In Time Sampling & In Time Shipment

* Quality Guarantee

* Free Sample Can Be Provided Some Time

* Low MOQ

* Reply in 24 hours and fast quotaion

How Ace Sure The Quality?

1) Ace proceed 4 times during production proceeding.

They are: raw material inspection, process machining inspection, mass production inspection, final inspection.

| Raw Material Inspection Reported | Process Maching Inspection Record | Mass Production Inspection Record | Final Inspection Reported |

2) After each inspection, a paper report will be checked out and recorded for future checking.

3)100% Inspected before Shipment. Inspection date report provided. And PPAP can be provided too.

How Many Equipments Does Ace Have?

10 CNC lathing machine with actual working tolerance ±0.02MM.

5 CNC lathing and milling center with actual working tolerance is ±0.02MM.

Drawing Format Can Done By Ace?

dwg, dxf, prt, iGS, step, stp, iges, slprt, asm, x_t files are all accepted.

What kinds of CNC machining product is suitable to send to Ace for quoation?

CNC machining product, CNC milling product, CNC lathing product, CNC turning product, CNC precision machining product, maching product, precision product and all machining parts used in different industrials such as: spray nozzle, car accessories, railway accessories, bathroom accessoires, equipemnt spare parts, pipe and fittings and so on.

| Condition: | New |

|---|---|

| Certification: | CE, RoHS |

| Standard: | ASTM |

| Customized: | Customized |

| Material: | Iron |

| Application: | Metal Processing Machinery Parts |

| Customization: |

Available

| Customized Request |

|---|

Are there different types of car pulleys, and how do they vary in applications?

Yes, there are different types of car pulleys, and they vary in applications based on their design, function, and the components they are connected to. Here's a detailed explanation of the different types of car pulleys and their varying applications:

- Idler Pulleys: Idler pulleys are stationary pulleys that guide and route the belt in a specific path. They are designed to maintain tension in the belt and ensure proper alignment between the driving and driven pulleys. Idler pulleys are commonly used in serpentine belt systems to guide the belt around various accessories, such as the alternator, power steering pump, and air conditioning compressor.

- Tensioner Pulleys: Tensioner pulleys are similar to idler pulleys but include a built-in mechanism to automatically maintain proper belt tension. They are commonly used in serpentine belt systems to provide constant tension on the belt, compensating for belt stretch and wear. Tensioner pulleys help prevent belt slippage, ensure efficient power transmission, and reduce the need for manual belt adjustments.

- Crankshaft Pulleys: Crankshaft pulleys are connected to the engine's crankshaft and are responsible for transmitting power from the engine to various accessories or components. They are usually larger in size and serve as the main driving pulleys in the engine's accessory drive system. Crankshaft pulleys are typically connected to the alternator, power steering pump, air conditioning compressor, and water pump.

- Supercharger Pulleys: Supercharger pulleys are specific to vehicles equipped with supercharger systems. These pulleys are connected to the supercharger and help drive it to compress the incoming air, resulting in increased engine performance. Supercharger pulleys come in different sizes or diameters, allowing for adjustments to the supercharger's speed and boost levels, which directly influences engine power output.

- Turbocharger Pulleys: Turbocharger pulleys are specific to vehicles equipped with turbocharger systems. Similar to supercharger pulleys, they are connected to the turbocharger and drive its turbine wheel using exhaust gases. Turbocharger pulleys, often referred to as turbine housings, come in various sizes and designs to optimize turbocharger spooling characteristics, boost levels, and overall performance.

- Accessory Pulleys: Accessory pulleys are connected to individual accessories in the engine's accessory drive system, such as the alternator, power steering pump, air conditioning compressor, and water pump. They transmit power from the crankshaft pulley to these components, allowing them to operate and perform their respective functions. Accessory pulleys may have different sizes, groove configurations, or designs based on the specific accessory they are driving.

The varying types of car pulleys mentioned above have specific applications within the vehicle's engine system. Idler pulleys and tensioner pulleys help guide and maintain proper tension in the belts, ensuring efficient power transmission. Crankshaft pulleys serve as the main driving pulleys, connecting the crankshaft to the engine's accessories. Supercharger and turbocharger pulleys are specific to forced induction systems, boosting engine performance. Accessory pulleys are connected to individual accessories, allowing them to operate and perform their intended functions.

It's important to note that the specific types and applications of car pulleys may vary depending on the vehicle make, model, and engine configuration. Manufacturers design and select pulleys based on the specific requirements and characteristics of the engine system.

How are car pulleys customized for specific makes and models of vehicles?

Car pulleys are customized to fit specific makes and models of vehicles to ensure proper compatibility, functionality, and performance. The customization process involves considerations such as the engine design, layout, accessory requirements, and desired performance characteristics. Here's a detailed explanation of how car pulleys are customized for specific makes and models of vehicles:

- Engine Specifications: Car pulleys are designed to match the specific engine specifications of each vehicle make and model. This includes considerations such as the number of cylinders, engine displacement, and power output. The pulley's size, shape, and weight distribution are tailored to accommodate the engine's physical dimensions and characteristics.

- Belt Routing: The pulleys are customized to align with the belt routing requirements of each vehicle. The placement and orientation of pulleys are carefully designed to ensure efficient and proper belt engagement with driven components. Belt routing may vary between different engine layouts (e.g., transverse or longitudinal), and the pulleys are adjusted accordingly to accommodate the specific routing needs of each vehicle.

- Accessory Compatibility: Car pulleys are customized to accommodate the specific accessory requirements of each vehicle. Different vehicles may have varying numbers and types of accessories, such as alternators, power steering pumps, air conditioning compressors, and water pumps. The pulleys are designed to match the specifications and power requirements of these accessories, ensuring compatibility and optimal performance.

- Tension and Load Requirements: Pulleys are customized to handle the specific tension and load requirements of each vehicle's engine and accessories. Factors such as belt tension, load forces, and operating conditions are taken into account during the customization process. The pulleys are engineered to withstand the anticipated loads and maintain proper belt tension to ensure reliable power transmission and prevent slippage.

- Performance Considerations: Car pulleys can be customized to achieve specific performance goals for each vehicle make and model. Performance-oriented vehicles may require pulleys designed to optimize power delivery, torque characteristics, or specific RPM ranges. Customization can involve adjusting the pulley sizes, ratios, or designs to fine-tune the engine's performance and meet the desired performance objectives.

- Manufacturing and Quality Control: The customization of car pulleys involves precise manufacturing processes to ensure accurate dimensions, tolerances, and material specifications. Pulleys are manufactured to meet the quality and performance standards required by the vehicle manufacturer. Strict quality control measures are implemented to verify the pulleys' performance, durability, and compatibility with the specific makes and models of vehicles.

In conclusion, car pulleys are customized for specific makes and models of vehicles through considerations such as engine specifications, belt routing, accessory compatibility, tension and load requirements, performance objectives, and meticulous manufacturing processes. Customized pulleys play a vital role in ensuring proper fitment, reliable power transmission, and optimal performance of the engine and its driven components. By tailoring the pulleys to the specific requirements of each vehicle, manufacturers can optimize performance, efficiency, and overall vehicle functionality.

What is a car pulley, and how is it used in automotive systems?

A car pulley is a mechanical component used in automotive systems to transfer power, drive auxiliary components, and facilitate the operation of various systems within a vehicle. It is a wheel-like device with a grooved rim that is typically made of metal or composite materials. Here's a detailed explanation of the car pulley and its applications in automotive systems:

A car pulley operates based on the principles of rotational motion. It is usually mounted on the engine crankshaft, which is connected to the pistons and converts the reciprocating motion of the pistons into rotational motion. The pulley is driven by the rotational motion of the crankshaft and is connected to other components or systems through belts or chains.

There are different types of car pulleys used in automotive systems, including:

- Accessory Pulleys: These pulleys are responsible for driving various accessory components in the vehicle, such as the alternator, power steering pump, water pump, and air conditioning compressor. The accessory pulleys are typically connected to these components through belts, such as the serpentine belt or V-belts, and transfer power from the engine to operate these systems.

- Tensioner Pulleys: Tensioner pulleys are used to maintain the proper tension of belts in the automotive system. They are designed to apply tension to the belts, ensuring that they remain properly seated on the pulleys and operate smoothly. Tensioner pulleys often have built-in mechanisms, such as springs or hydraulic systems, to automatically adjust the tension and compensate for belt stretch or wear.

- Idler Pulleys: Idler pulleys are used to change the direction of a belt or provide additional support and tension to the belt. They are stationary pulleys that guide the belt around various components and help maintain proper belt alignment. Idler pulleys play a crucial role in ensuring smooth belt operation and preventing slippage or excessive wear.

- Crankshaft Pulley: The crankshaft pulley is directly attached to the crankshaft and is responsible for driving the other pulleys and components in the accessory drive system. It is often a larger pulley compared to the accessory pulleys and serves as the starting point for power transfer through belts or chains.

In automotive systems, car pulleys are used to transmit power efficiently and reliably from the engine to various components and systems. They enable the operation of critical systems such as the electrical charging system (alternator), power steering system (power steering pump), cooling system (water pump), and air conditioning system (air conditioning compressor).

The rotation of the car pulleys is synchronized with the engine speed, allowing the driven components to operate at the appropriate speed and deliver the required performance. Proper belt tension, guided by tensioner and idler pulleys, ensures efficient power transfer and prevents belt slippage or excessive wear. Additionally, car pulleys are designed to handle the high temperatures and demanding conditions of the engine compartment.

Overall, car pulleys are essential components in automotive systems, enabling the efficient and reliable operation of auxiliary systems and ensuring the smooth functioning of a vehicle's various functions.

editor by CX

2023-10-08