Product Description

| Product name | Hanging Door Rollers Car Engine Pulley Heavy Duty Rope Pulley |

| Model number | Door Roller |

| Bore size | 5-10mm |

| Outside size | 5-5mm |

| Bearing material | Chrome steel, carbon steel, iron, high carbon steel |

| MOQ | 50000 PCS |

| Price terms | EXW, FOB, CIF |

| Payment terms | T/T, L/C, Paypal, Credit card |

| Production time | Depends on the quantity, normally 35-45 days. |

| Package | PE bag+white box+outer carton+pallet, or as customers' requirement. |

| Application | Used in door, window, furniture and sports equipment. |

1. Pre-sale service: Our professional sales will reply your inquiry within 48 hours and introduce the structure and usage of the products.

2. On-purchase service: After customers placed the order, we will prepare the goods ASAP to make sure the delivery on time. Any delay will be notified in advance.

3. After-sale service: If there is any damage during delivery, the cost will be taken by our company and if there is problem during the warranty period, we will replace or refund it.

4. OEM service: We have advanced technology and experienced technicians to support the professional customized all kinds of bearing to meet different requirements.

Q: Are your company is a trading company or manufacturer?

A:We have our own factory as well we do the trade by our selves.

Q:How long is your delivery time?

A:Usually 5-10 days if we have the stock,if not,it will be 25-35 days. But it always depend on the quantity.

Q:Do you provide the free samples?

A:Yes,we'd like to.But you need to pay the freight fee,or we will return the cost when receiving your order.

Q:Can you do the OEM/ODM services?

A:Of course we can,We can be customized according to your requirements or drawings.

| Certification: | CE |

|---|---|

| Splittable: | Splittable |

| Material: | Nylon |

| Groove Diameter: | Customized |

| Inner Hole: | 5-10mm |

| Color: | Orange, Balck, Green, Yellow, Red,Blue |

| Samples: |

US$ 0.25/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

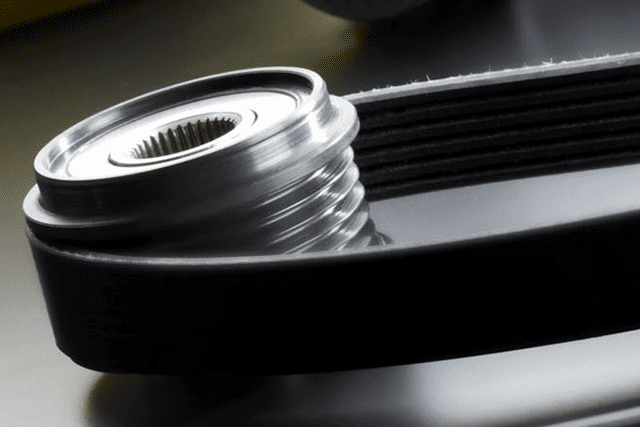

Can car pulleys be a source of noise or vibration in a vehicle?

Yes, car pulleys can indeed be a source of noise or vibration in a vehicle. Several factors related to the pulleys can contribute to noise and vibration issues. Here's a detailed explanation:

Pulley Misalignment:

If the car pulleys are not properly aligned with other components, such as belts or accessories, it can cause misalignment-related problems. Misaligned pulleys can lead to increased friction, belt wear, and uneven power transmission. This can result in noise and vibration in the vehicle. Common causes of pulley misalignment include improper installation, worn-out components, or damage to the pulley system.

Worn-out or Damaged Pulley Bearings:

The pulleys in a vehicle incorporate bearings that allow smooth rotation. Over time, these bearings can wear out or become damaged, resulting in increased friction or play. Worn-out or damaged pulley bearings can lead to noise and vibration issues. The noise may manifest as squeaking, grinding, or rumbling sounds, especially when the pulley is rotating. Additionally, the vibration caused by faulty bearings can be felt through the vehicle's steering wheel or other components.

Belt Tension and Condition:

The tension of the belts connected to the pulleys is crucial for their proper operation. If the belt tension is too loose or too tight, it can cause problems. A loose belt may slip on the pulley, resulting in noise and vibration. On the other hand, an excessively tight belt can put excessive strain on the pulley and other components, leading to noise and vibration as well. Furthermore, worn-out or damaged belts can also contribute to noise issues when they interact with the pulleys.

Accessory Component Issues:

In addition to the pulleys themselves, noise and vibration can also be caused by issues with the accessory components driven by the pulley system. For example, a malfunctioning alternator, power steering pump, air conditioning compressor, or water pump can generate noise or vibration that is transmitted through the pulleys. Such issues may be related to worn-out bearings, unbalanced components, or internal mechanical problems.

Other Factors:

It's important to note that while car pulleys can contribute to noise and vibration, they are not the sole potential source. Other factors such as engine problems, exhaust system issues, suspension components, or tire irregularities can also cause noise and vibration in a vehicle. Therefore, a comprehensive diagnosis is necessary to identify the exact source of the noise or vibration.

In summary, car pulleys can be a source of noise or vibration in a vehicle. Pulley misalignment, worn-out or damaged bearings, improper belt tension, and issues with accessory components can all contribute to these problems. If you experience unusual noise or vibration in your vehicle, it is advisable to have it inspected by a qualified mechanic to identify and address the underlying cause.

What is the significance of proper alignment and tensioning in car pulley systems?

Proper alignment and tensioning are crucial factors in the functioning and reliability of car pulley systems. The alignment ensures that the pulleys are correctly positioned and oriented, while the tensioning ensures that the belts connecting the pulleys are appropriately tensioned. Here's a detailed explanation of the significance of proper alignment and tensioning in car pulley systems:

- Efficient Power Transmission: Proper alignment of the pulleys ensures that the belts maintain optimal contact with the pulley grooves. This allows for efficient power transmission from the engine to the driven components, such as the alternator, power steering pump, air conditioning compressor, and water pump. Misaligned pulleys can cause belt slippage, reducing power delivery and affecting the performance of these components.

- Prevention of Belt Wear and Damage: Correct alignment and tensioning help prevent excessive belt wear and damage. Misalignment can cause the belts to rub against the pulley edges or sides, leading to accelerated wear, fraying, or even belt failure. Improper tensioning can result in slippage, causing the belts to generate heat, wear unevenly, and potentially snap. Proper alignment and tensioning distribute the load evenly across the belts, minimizing wear and extending their lifespan.

- Reduced Noise and Vibration: Misaligned or improperly tensioned pulleys can result in increased noise and vibration. Misalignment causes the belts to oscillate or vibrate, generating noise and potentially creating an unpleasant driving experience. Proper alignment and tensioning reduce belt vibrations, resulting in smoother and quieter operation of the pulley system.

- Optimal Performance and Efficiency: Proper alignment and tensioning contribute to optimal performance and efficiency of the engine and the driven components. When the pulleys are aligned correctly, the belts operate at their designed angles, maximizing contact area and minimizing energy losses. This improves the overall efficiency of the system and ensures that the driven components receive the necessary power for optimal performance.

- Prevention of Component Damage: Misalignment and improper tensioning can place excessive stress on the pulleys and the driven components. This can lead to premature component failure, such as bearing damage, shaft wear, or seal leaks. Proper alignment and tensioning help distribute the loads evenly, reducing stress on the pulleys and components, and minimizing the risk of damage or failure.

- Enhanced Belt Life: Correct alignment and tensioning contribute to the longevity of the belts. When the pulleys are properly aligned, and the belts are adequately tensioned, the belts experience less stress, wear, and fatigue. This extends the lifespan of the belts, reducing the frequency of belt replacements and associated maintenance costs.

In conclusion, proper alignment and tensioning are essential for the reliable and efficient operation of car pulley systems. They ensure efficient power transmission, prevent belt wear and damage, reduce noise and vibration, optimize performance and efficiency, prevent component damage, and enhance the lifespan of the belts. Regular inspections and adjustments should be performed to maintain proper alignment and tensioning, ensuring the longevity and reliable functioning of the pulley system and its associated components.

How do car pulleys contribute to the proper functioning of the engine?

Car pulleys play a crucial role in ensuring the proper functioning of the engine. Their contribution is vital for power transmission, belt guidance, load adaptation, and accessory operation. Here's a detailed explanation of how car pulleys contribute to the engine's proper functioning:

- Power Transmission: Car pulleys are integral for power transmission within the engine. The crankshaft pulley, connected directly to the engine's crankshaft, serves as the starting point for power transfer. As the engine rotates, the crankshaft pulley rotates, transmitting power to other components and systems through belts or chains. This power transmission enables the engine to drive various systems, such as the alternator, water pump, power steering pump, and air conditioning compressor.

- Belt Guidance: Pulleys provide guidance for belts within the engine. The grooved rim on the pulleys serves as a track for the belts, ensuring they remain properly seated and aligned during operation. By guiding the belts, pulleys prevent slippage and ensure efficient power transfer. Proper belt guidance is essential for maintaining the synchronization between the engine's crankshaft and driven components, such as the camshaft(s) in an overhead camshaft engine.

- Load Adaptation: Car pulleys allow for load adaptation within the engine. Load adaptation refers to the adjustment of the effective diameter or speed ratio of pulleys to optimize power delivery based on the engine's operating conditions. Variable pulleys or movable flanges can be used to adjust the position of belts or chains, enabling the engine to adapt to varying load demands. Load adaptation ensures that the engine operates efficiently and delivers the required power for different driving situations and loads.

- Accessory Operation: Car pulleys are essential for the operation of various engine accessories. The engine's accessory pulleys, driven by the crankshaft, transmit power to components such as the alternator, power steering pump, air conditioning compressor, and water pump. These accessories are vital for electrical generation, power steering assistance, air conditioning, and coolant circulation, respectively. The pulleys ensure that the accessories operate synchronously with the engine, enabling their proper functioning.

Overall, car pulleys contribute significantly to the proper functioning of the engine by facilitating power transmission, guiding belts, adapting to load conditions, and enabling the operation of essential accessories. Their role ensures that the engine operates efficiently, delivers power to various systems, and functions reliably under different driving conditions.

editor by CX

2023-10-08