Product Description

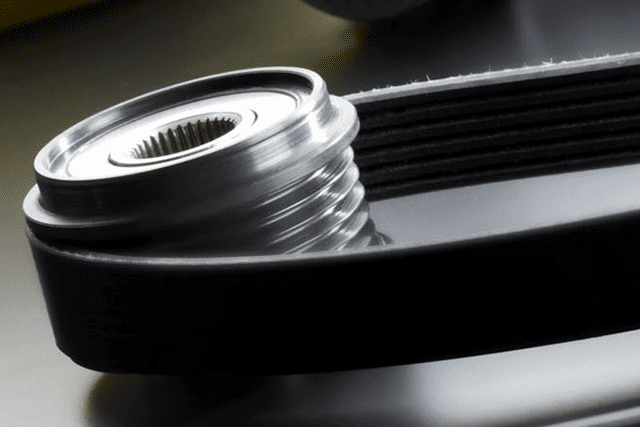

| MIC NO. | OEM.NO | APPLICATION | YEAR | PHOTO |

| TB33FD9101 | 201160CP FORD : 105719 FORD : 96BF6A228AB MAZDA : 1E571980 |

FORD ESCORT VI (GAL, AAL, ABL) 1.3 FORD ESCORT VI Saloon (GAL, AFL) 1.3 FORD ESCORT VI Turnier (GAL, ANL) 1.3 FORD FIESTA Box (F3L, F5L) 1.3 FORD FIESTA IV (JA_, JB_) 1.3 i FORD KA (RB_) 1.0 i FORD KA (RB_) 1.3 i MAZDA 121 III (JASM, JBSM) 1.3 |

1995-1998 1995-1999 1995-1999 1991-1996 1995-2002 1997-1999 1996-2008 1996-2003 |

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Online Technical Support |

|---|---|

| Warranty: | One Year |

| Car Make: | FORD |

| Car Model: | ESCORT VI (GAL, AAL, ABL) 1.3 |

| MOQ: | 100 PCS |

| Sample: | Available |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Are there different types of car pulleys, and how do they vary in applications?

Yes, there are different types of car pulleys, and they vary in applications based on their design, function, and the components they are connected to. Here's a detailed explanation of the different types of car pulleys and their varying applications:

- Idler Pulleys: Idler pulleys are stationary pulleys that guide and route the belt in a specific path. They are designed to maintain tension in the belt and ensure proper alignment between the driving and driven pulleys. Idler pulleys are commonly used in serpentine belt systems to guide the belt around various accessories, such as the alternator, power steering pump, and air conditioning compressor.

- Tensioner Pulleys: Tensioner pulleys are similar to idler pulleys but include a built-in mechanism to automatically maintain proper belt tension. They are commonly used in serpentine belt systems to provide constant tension on the belt, compensating for belt stretch and wear. Tensioner pulleys help prevent belt slippage, ensure efficient power transmission, and reduce the need for manual belt adjustments.

- Crankshaft Pulleys: Crankshaft pulleys are connected to the engine's crankshaft and are responsible for transmitting power from the engine to various accessories or components. They are usually larger in size and serve as the main driving pulleys in the engine's accessory drive system. Crankshaft pulleys are typically connected to the alternator, power steering pump, air conditioning compressor, and water pump.

- Supercharger Pulleys: Supercharger pulleys are specific to vehicles equipped with supercharger systems. These pulleys are connected to the supercharger and help drive it to compress the incoming air, resulting in increased engine performance. Supercharger pulleys come in different sizes or diameters, allowing for adjustments to the supercharger's speed and boost levels, which directly influences engine power output.

- Turbocharger Pulleys: Turbocharger pulleys are specific to vehicles equipped with turbocharger systems. Similar to supercharger pulleys, they are connected to the turbocharger and drive its turbine wheel using exhaust gases. Turbocharger pulleys, often referred to as turbine housings, come in various sizes and designs to optimize turbocharger spooling characteristics, boost levels, and overall performance.

- Accessory Pulleys: Accessory pulleys are connected to individual accessories in the engine's accessory drive system, such as the alternator, power steering pump, air conditioning compressor, and water pump. They transmit power from the crankshaft pulley to these components, allowing them to operate and perform their respective functions. Accessory pulleys may have different sizes, groove configurations, or designs based on the specific accessory they are driving.

The varying types of car pulleys mentioned above have specific applications within the vehicle's engine system. Idler pulleys and tensioner pulleys help guide and maintain proper tension in the belts, ensuring efficient power transmission. Crankshaft pulleys serve as the main driving pulleys, connecting the crankshaft to the engine's accessories. Supercharger and turbocharger pulleys are specific to forced induction systems, boosting engine performance. Accessory pulleys are connected to individual accessories, allowing them to operate and perform their intended functions.

It's important to note that the specific types and applications of car pulleys may vary depending on the vehicle make, model, and engine configuration. Manufacturers design and select pulleys based on the specific requirements and characteristics of the engine system.

What role do car pulleys play in controlling and synchronizing engine components?

Car pulleys play a crucial role in controlling and synchronizing engine components, ensuring their proper operation and coordination. They are responsible for transmitting power from the engine's crankshaft to various driven components and systems. Here's an in-depth explanation of the role car pulleys play in controlling and synchronizing engine components:

- Power Transmission: Car pulleys, in conjunction with belts or chains, transmit rotational power from the engine's crankshaft to driven components and systems. The pulleys are connected to the crankshaft and rotate as the engine runs. As the crankshaft pulley turns, it drives the belts or chains that are connected to other pulleys located on components such as the alternator, power steering pump, air conditioning compressor, water pump, and more. This power transmission enables these components to function and perform their respective tasks.

- Belt Routing: Car pulleys play a critical role in determining the routing of belts throughout the engine. The pulley locations and orientations are carefully designed to ensure the most efficient and appropriate path for the belts to wrap around. Proper belt routing enables the pulleys to drive the desired components without interference, minimizing the risk of belt slippage, misalignment, or contact with other engine parts.

- Tension Control: Car pulleys contribute to controlling the tension in belts or chains. Tension is crucial to ensure proper power transmission and prevent slippage. Some pulleys incorporate tensioner mechanisms that automatically adjust the tension in the belts to compensate for wear and stretch over time. These tensioners help maintain optimal belt tension, ensuring reliable power delivery to the driven components.

- Timing and Synchronization: In engines with overhead camshafts (OHC), car pulleys play a vital role in controlling the timing and synchronization of valve operation. The pulleys are connected to the camshafts, which open and close the engine's valves. The timing and synchronization of valve operation are critical for proper combustion and engine performance. Timing pulleys, often toothed or geared, ensure precise timing and synchronization between the crankshaft and camshaft(s), enabling efficient intake and exhaust valve operation.

- Accessory Operation: Car pulleys facilitate the operation of various engine accessories. The pulleys connected to components like the alternator, power steering pump, and air conditioning compressor enable these accessories to receive power and perform their functions. By controlling the rotational speed and power delivery, the pulleys ensure that the accessories operate at the required speeds and provide the necessary power for optimal performance.

- Harmonic Balancing: Some car pulleys, particularly the crankshaft pulley, incorporate harmonic balancers or dampers. These components help reduce vibrations and torsional forces generated by the engine's reciprocating motion. The harmonic balancer absorbs and dissipates these vibrations, protecting the engine and its components from excessive wear and potential damage.

In summary, car pulleys play a vital role in controlling and synchronizing engine components. They facilitate power transmission, control belt routing, adjust belt tension, ensure timing and synchronization of valve operation, enable accessory operation, and contribute to harmonic balancing. Properly designed and maintained pulleys are essential for the reliable and efficient operation of engine components, ensuring smooth coordination and optimal performance of the engine as a whole.

How does the size and design of a car pulley impact engine performance?

The size and design of a car pulley have a significant impact on engine performance. The pulley's size and design influence critical factors such as power output, torque characteristics, component speeds, and efficiency. Here's a detailed explanation of how the size and design of a car pulley impact engine performance:

- Power Output: The size of the pulley directly affects the power output of the engine. A larger pulley on the crankshaft will result in a slower rotational speed, reducing the power output. Conversely, a smaller pulley will increase the rotational speed and potentially boost power output. Modifying the size of the pulley can be used to fine-tune the engine's power delivery characteristics and optimize performance for specific applications.

- Torque Characteristics: The size and design of the pulley impact the torque characteristics of the engine. A smaller pulley can increase the torque at lower engine speeds, providing better low-end responsiveness and acceleration. On the other hand, a larger pulley can improve top-end torque, allowing for higher speeds. The choice of pulley size and design should consider the desired torque curve and the engine's intended use.

- Component Speeds: The size and design of pulleys affect the rotational speeds of various engine components. For example, the size of the crankshaft pulley determines the speeds at which the driven components, such as the alternator, water pump, and power steering pump, operate. Proper sizing and design ensure that the components operate within their optimal speed ranges, maximizing their efficiency and performance.

- Belt Tension and Slippage: The size and design of the pulley influence the tension and potential slippage of the belts connected to it. A properly sized pulley ensures the correct tension in the belts, preventing excessive slippage that can lead to power loss and reduced efficiency. The pulley's design, including the shape and depth of the grooves, also plays a role in maintaining proper belt engagement and minimizing slippage.

- Efficiency: The size and design of the pulley impact the overall efficiency of the engine. An appropriately sized pulley helps optimize power transmission, minimizing energy losses due to belt slippage or excessive friction. Additionally, pulleys with well-designed grooves and smooth surfaces reduce friction, improving overall efficiency by reducing energy wastage and enhancing the engine's ability to convert fuel into useful work.

- Accessory Operation: The size and design of pulleys influence the operation of engine accessories. Properly sized pulleys ensure that the accessories, such as the alternator, power steering pump, and air conditioning compressor, operate at the correct speeds to provide optimal performance. A mismatch between pulley size and accessory requirements can lead to underperformance or excessive load on the engine.

In conclusion, the size and design of a car pulley have a significant impact on engine performance. They affect power output, torque characteristics, component speeds, belt tension, efficiency, and accessory operation. Careful consideration of pulley size and design is crucial in optimizing engine performance for specific requirements, balancing power, torque, and efficiency to achieve the desired performance characteristics.

editor by CX

2024-01-10