Product Description

Company Profile

HangZhou Doerbee International Trade Co. , Ltd. , located in HangZhou hi-tech Development Zone, ZheJiang Province, the company's main auto parts, mechanical and electrical supplies. Our company has established long-term and stable cooperative relations with many auto parts factories in ZHangZhoug and ZheJiang provinces. We value credit, abide by contracts, guarantee product quality, win the trust of our customers, and make every effort to follow their needs, continuous product innovation and service improvement. OEM, sample can be customized. We will gradually improve the product types and details, if you have non-standard products need us to help you find Chinese manufacturers, please contact us, send samples, we will be your most responsible and professional partner in China. Looking CHINAMFG to working with you.

Every month, we will go back and forth to each auto parts manufacturer to find and compare all kinds of high quality and low price products for you. If you have samples, but can not confirm the model or name, you can also send samples to us, we will try our best to find out the sample manufacturers in China, compare the quality for you, and provide quotation. We represent all kinds of auto parts and mechanical and electrical products, in the future we will continue to improve the product category, please pay attention to us, any need, please feel free to contact us. At present, there are more than 3.3

Q1. How to buy?

A1:Large quantity for more discount : Inquiry → Quotation → Price resonable → Check with specification → Proforma Invoice sent → Payment made → Product shipment → Customer

Q2. What is your terms of payment?

A2:T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages before you pay the balance.

Q3. How about your delivery time?

A3:Generally, it will take 20 to 40 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q4. Can you produce according to the samples?

A4:Yes, we can produce by your samples or technical drawings.

Q5. What is your sample policy?

A5:We can supply the sample if we have ready parts in stock, but the customers have to pay the sample and courier cost.

Q6. Do you test all your goods before delivery?

A6:Yes, We will take 100% testing and photos before delivery, and keep communication with you at any time.

Q7: How do you make our business long-term and good relationship?

A7:We are not only partners, but also friends. We will try our best to provide you with the most cost-effective products. If you have any goods that are difficult to purchase, we will try our best to find them in China. We will become your most trusted buyers in China.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | 100000 Km |

|---|---|

| Warranty: | 2 Years |

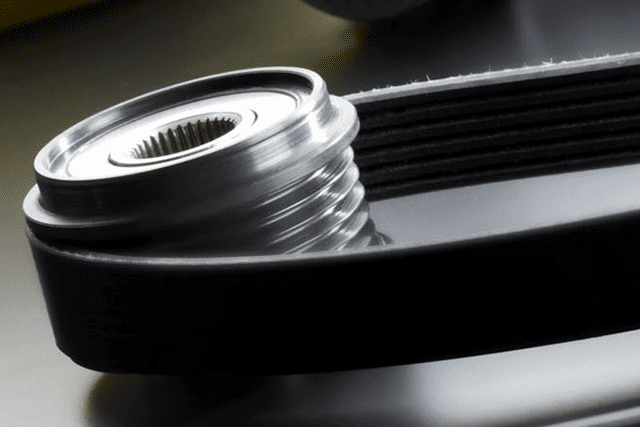

| Type: | Auto Clutch Bearing |

| Material: | Carbon Steel |

| Tolerance: | P5 |

| Certification: | TS16949 |

| Samples: |

US$ 8/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can car pulleys be a source of noise or vibration in a vehicle?

Yes, car pulleys can indeed be a source of noise or vibration in a vehicle. Several factors related to the pulleys can contribute to noise and vibration issues. Here's a detailed explanation:

Pulley Misalignment:

If the car pulleys are not properly aligned with other components, such as belts or accessories, it can cause misalignment-related problems. Misaligned pulleys can lead to increased friction, belt wear, and uneven power transmission. This can result in noise and vibration in the vehicle. Common causes of pulley misalignment include improper installation, worn-out components, or damage to the pulley system.

Worn-out or Damaged Pulley Bearings:

The pulleys in a vehicle incorporate bearings that allow smooth rotation. Over time, these bearings can wear out or become damaged, resulting in increased friction or play. Worn-out or damaged pulley bearings can lead to noise and vibration issues. The noise may manifest as squeaking, grinding, or rumbling sounds, especially when the pulley is rotating. Additionally, the vibration caused by faulty bearings can be felt through the vehicle's steering wheel or other components.

Belt Tension and Condition:

The tension of the belts connected to the pulleys is crucial for their proper operation. If the belt tension is too loose or too tight, it can cause problems. A loose belt may slip on the pulley, resulting in noise and vibration. On the other hand, an excessively tight belt can put excessive strain on the pulley and other components, leading to noise and vibration as well. Furthermore, worn-out or damaged belts can also contribute to noise issues when they interact with the pulleys.

Accessory Component Issues:

In addition to the pulleys themselves, noise and vibration can also be caused by issues with the accessory components driven by the pulley system. For example, a malfunctioning alternator, power steering pump, air conditioning compressor, or water pump can generate noise or vibration that is transmitted through the pulleys. Such issues may be related to worn-out bearings, unbalanced components, or internal mechanical problems.

Other Factors:

It's important to note that while car pulleys can contribute to noise and vibration, they are not the sole potential source. Other factors such as engine problems, exhaust system issues, suspension components, or tire irregularities can also cause noise and vibration in a vehicle. Therefore, a comprehensive diagnosis is necessary to identify the exact source of the noise or vibration.

In summary, car pulleys can be a source of noise or vibration in a vehicle. Pulley misalignment, worn-out or damaged bearings, improper belt tension, and issues with accessory components can all contribute to these problems. If you experience unusual noise or vibration in your vehicle, it is advisable to have it inspected by a qualified mechanic to identify and address the underlying cause.

What role do car pulleys play in controlling and synchronizing engine components?

Car pulleys play a crucial role in controlling and synchronizing engine components, ensuring their proper operation and coordination. They are responsible for transmitting power from the engine's crankshaft to various driven components and systems. Here's an in-depth explanation of the role car pulleys play in controlling and synchronizing engine components:

- Power Transmission: Car pulleys, in conjunction with belts or chains, transmit rotational power from the engine's crankshaft to driven components and systems. The pulleys are connected to the crankshaft and rotate as the engine runs. As the crankshaft pulley turns, it drives the belts or chains that are connected to other pulleys located on components such as the alternator, power steering pump, air conditioning compressor, water pump, and more. This power transmission enables these components to function and perform their respective tasks.

- Belt Routing: Car pulleys play a critical role in determining the routing of belts throughout the engine. The pulley locations and orientations are carefully designed to ensure the most efficient and appropriate path for the belts to wrap around. Proper belt routing enables the pulleys to drive the desired components without interference, minimizing the risk of belt slippage, misalignment, or contact with other engine parts.

- Tension Control: Car pulleys contribute to controlling the tension in belts or chains. Tension is crucial to ensure proper power transmission and prevent slippage. Some pulleys incorporate tensioner mechanisms that automatically adjust the tension in the belts to compensate for wear and stretch over time. These tensioners help maintain optimal belt tension, ensuring reliable power delivery to the driven components.

- Timing and Synchronization: In engines with overhead camshafts (OHC), car pulleys play a vital role in controlling the timing and synchronization of valve operation. The pulleys are connected to the camshafts, which open and close the engine's valves. The timing and synchronization of valve operation are critical for proper combustion and engine performance. Timing pulleys, often toothed or geared, ensure precise timing and synchronization between the crankshaft and camshaft(s), enabling efficient intake and exhaust valve operation.

- Accessory Operation: Car pulleys facilitate the operation of various engine accessories. The pulleys connected to components like the alternator, power steering pump, and air conditioning compressor enable these accessories to receive power and perform their functions. By controlling the rotational speed and power delivery, the pulleys ensure that the accessories operate at the required speeds and provide the necessary power for optimal performance.

- Harmonic Balancing: Some car pulleys, particularly the crankshaft pulley, incorporate harmonic balancers or dampers. These components help reduce vibrations and torsional forces generated by the engine's reciprocating motion. The harmonic balancer absorbs and dissipates these vibrations, protecting the engine and its components from excessive wear and potential damage.

In summary, car pulleys play a vital role in controlling and synchronizing engine components. They facilitate power transmission, control belt routing, adjust belt tension, ensure timing and synchronization of valve operation, enable accessory operation, and contribute to harmonic balancing. Properly designed and maintained pulleys are essential for the reliable and efficient operation of engine components, ensuring smooth coordination and optimal performance of the engine as a whole.

What are the advantages of using high-quality pulleys in car engines?

Using high-quality pulleys in car engines offers several advantages that contribute to the overall performance, reliability, and efficiency of the vehicle. Here are the key benefits of using high-quality pulleys:

- Enhanced Durability: High-quality pulleys are built to withstand the demanding operating conditions within car engines. They are constructed using durable materials and undergo rigorous manufacturing processes, ensuring they can endure high temperatures, vibrations, and mechanical stresses. Improved durability reduces the likelihood of pulley failure, prolongs their lifespan, and minimizes the need for frequent replacements.

- Optimized Power Transmission: High-quality pulleys are designed to provide efficient power transmission from the engine to driven components. They have precise dimensions, well-engineered grooves, and optimal surface finishes that enable proper belt engagement and reduce slippage. Efficient power transmission ensures that the driven components receive the power they require, resulting in improved overall performance and functionality of the engine.

- Reduced Noise and Vibration: High-quality pulleys are carefully balanced and engineered to minimize noise and vibration. They undergo stringent quality control measures to ensure smooth operation and minimize unwanted vibrations that can cause noise and discomfort. Reduced noise and vibration contribute to a quieter and more comfortable driving experience.

- Improved Belt Life: High-quality pulleys help extend the life of belts connected to them. The precise design and smooth surfaces of these pulleys reduce friction and wear on the belts, resulting in increased belt longevity. By minimizing belt wear, high-quality pulleys reduce the risk of belt failure, improve reliability, and decrease maintenance costs associated with belt replacements.

- Precision and Accuracy: High-quality pulleys are manufactured to strict tolerances, ensuring precision and accuracy in their dimensions and performance. This precision helps maintain proper belt alignment, tension, and synchronization. Precise pulleys ensure that the belts operate optimally, preventing misalignment, slippage, or timing errors, which can negatively impact engine performance and potentially cause damage to components.

- Efficient System Operation: The use of high-quality pulleys promotes efficient operation of various engine systems and accessories. By providing reliable power transmission and proper belt engagement, these pulleys contribute to the effective functioning of systems such as the alternator, power steering, air conditioning, and water pump. Efficient system operation enhances overall vehicle performance, fuel efficiency, and driver satisfaction.

In summary, high-quality pulleys in car engines offer advantages such as enhanced durability, optimized power transmission, reduced noise and vibration, improved belt life, precision and accuracy, and efficient system operation. Investing in high-quality pulleys ensures the long-term reliability, performance, and efficiency of the engine and contributes to a smoother and more enjoyable driving experience.

editor by CX

2024-04-24