Product Description

Product Description

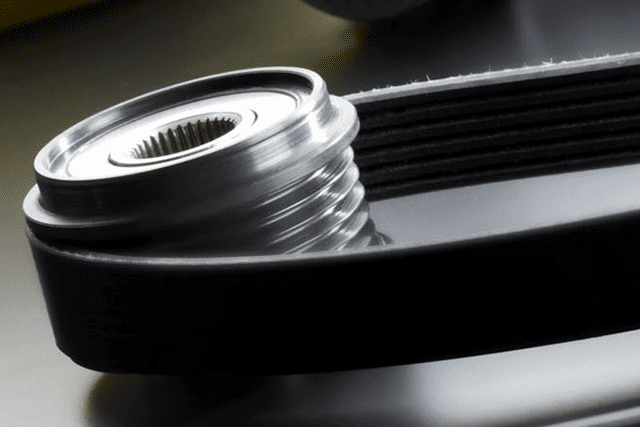

| Product Name | Belt tensioner | Brand | Original |

| Car Model | FORD TRANSIT V347 | Application | Engine parts |

| OEM | YC15-6A228-AG/YC15 6A228 AG | Quality | Original |

| Size | 20CM*15CM*15CM | G.W. | 2KG |

Detailed Photos

Certifications

Company Profile

Packaging & Shipping

Our Advantages

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | 12 Months |

|---|---|

| Warranty: | 12 Months |

| Certification: | CCC |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do you select the right car pulley for a specific automotive repair or upgrade?

Selecting the right car pulley for a specific automotive repair or upgrade requires careful consideration of various factors. Here's a detailed explanation of the steps involved in selecting the right car pulley:

- Identify the Specific Requirement: Determine the purpose of the car pulley. Are you replacing a faulty pulley, upgrading for improved performance, or modifying the engine system? Identifying the specific requirement helps narrow down the options and select the appropriate type of pulley.

- Refer to the Vehicle's Specifications: Consult the vehicle's specifications, such as the owner's manual or manufacturer's guidelines, to gather information about the original equipment pulley specifications. This includes details like the pulley's diameter, width, groove configuration, and other specific requirements. Matching these specifications ensures compatibility and proper fitment.

- Research and Compatibility: Conduct thorough research to identify aftermarket pulleys or upgrades available for your vehicle. Look for reputable manufacturers or suppliers that offer pulleys specifically designed for your vehicle make, model, and engine configuration. Check for compatibility with your engine system, accessory drive setup, and any other relevant considerations.

- Consider Performance and Design: If you are upgrading or modifying the engine system, consider performance-oriented pulleys that can enhance power delivery, reduce rotational inertia, or improve efficiency. Look for lightweight materials, optimized designs, or adjustable pulleys that allow customization based on your specific needs.

- Consult with Experts: Seek advice from automotive professionals, such as mechanics or performance specialists, who have expertise in car pulleys. They can provide insights, recommendations, and guidance based on their experience and knowledge. They may suggest specific brands, models, or configurations that are suitable for your intended use.

- Quality and Reliability: Prioritize pulleys that are manufactured by reputable brands known for their quality and reliability. Read customer reviews, assess the manufacturer's reputation, and consider factors like warranty coverage and product support. Choosing a high-quality pulley ensures durability, longevity, and optimal performance.

It's important to note that the selection process may vary depending on the specific automotive repair or upgrade. For routine replacements, it is generally recommended to use OEM-equivalent pulleys to maintain compatibility and performance. However, for performance upgrades or modifications, aftermarket pulleys designed for specific applications may be more suitable.

Ultimately, selecting the right car pulley requires a combination of research, consideration of the vehicle's specifications, compatibility with the engine system, performance requirements, and expert advice. Taking the time to make an informed decision ensures that you choose the appropriate pulley for your automotive repair or upgrade, leading to reliable and efficient operation.

Can car pulleys be upgraded or replaced to enhance engine performance?

Yes, car pulleys can be upgraded or replaced to enhance engine performance. Upgrading or replacing pulleys is a common modification made by automotive enthusiasts and performance-oriented vehicle owners. Here's a detailed explanation of how car pulleys can be upgraded or replaced to enhance engine performance:

- Lightweight Pulleys: One popular upgrade is the installation of lightweight pulleys. Lightweight pulleys are typically made from materials like aluminum or other high-strength alloys. By reducing the weight of the pulleys, rotational inertia is decreased, resulting in improved throttle response and faster revving. Lighter pulleys can also reduce parasitic drag on the engine, allowing more power to be transferred to the wheels.

- Performance Pulley Designs: Performance-oriented pulley designs may feature altered dimensions or profiles, such as different groove configurations or diameter ratios. These modifications aim to optimize power delivery, torque characteristics, or specific RPM ranges. Performance pulleys are designed to enhance engine performance in terms of horsepower, torque, or overall responsiveness.

- Underdrive Pulley Kits: Underdrive pulley kits are aftermarket upgrades that incorporate a combination of smaller diameter pulleys for various driven components, such as the alternator, power steering pump, and water pump. These pulleys are designed to reduce the speed at which these accessories operate, reducing their power consumption and freeing up engine power for increased performance.

- Custom Pulley Tuning: Some vehicles may benefit from custom pulley tuning, where pulley sizes or ratios are modified based on the specific requirements and goals of the engine. This tuning process involves careful analysis, calculation, and adjustment of the pulley sizes to optimize power delivery, boost efficiency, or achieve specific performance objectives.

- Supercharger or Turbocharger Pulleys: In forced induction systems like superchargers or turbochargers, pulleys play a crucial role in controlling the boost pressure and overall performance. Upgrading or replacing the pulleys in these systems can allow for increased boost levels, resulting in higher horsepower and torque outputs. However, it's important to ensure that the engine and supporting components can handle the increased stress and demands associated with higher boost levels.

- Professional Installation and Tuning: Upgrading or replacing car pulleys for performance purposes often requires professional installation and tuning. Proper installation ensures that the pulleys are correctly aligned, securely mounted, and compatible with the engine and driven components. Additionally, tuning may be necessary to optimize the engine's performance parameters and ensure safe and reliable operation.

In summary, car pulleys can be upgraded or replaced to enhance engine performance. Upgrades may include lightweight pulleys, performance pulley designs, underdrive pulley kits, custom pulley tuning, or specific modifications for forced induction systems. It's important to consider the compatibility, installation, and tuning requirements associated with pulley upgrades to achieve the desired performance enhancements safely and effectively.

What is a car pulley, and how is it used in automotive systems?

A car pulley is a mechanical component used in automotive systems to transfer power, drive auxiliary components, and facilitate the operation of various systems within a vehicle. It is a wheel-like device with a grooved rim that is typically made of metal or composite materials. Here's a detailed explanation of the car pulley and its applications in automotive systems:

A car pulley operates based on the principles of rotational motion. It is usually mounted on the engine crankshaft, which is connected to the pistons and converts the reciprocating motion of the pistons into rotational motion. The pulley is driven by the rotational motion of the crankshaft and is connected to other components or systems through belts or chains.

There are different types of car pulleys used in automotive systems, including:

- Accessory Pulleys: These pulleys are responsible for driving various accessory components in the vehicle, such as the alternator, power steering pump, water pump, and air conditioning compressor. The accessory pulleys are typically connected to these components through belts, such as the serpentine belt or V-belts, and transfer power from the engine to operate these systems.

- Tensioner Pulleys: Tensioner pulleys are used to maintain the proper tension of belts in the automotive system. They are designed to apply tension to the belts, ensuring that they remain properly seated on the pulleys and operate smoothly. Tensioner pulleys often have built-in mechanisms, such as springs or hydraulic systems, to automatically adjust the tension and compensate for belt stretch or wear.

- Idler Pulleys: Idler pulleys are used to change the direction of a belt or provide additional support and tension to the belt. They are stationary pulleys that guide the belt around various components and help maintain proper belt alignment. Idler pulleys play a crucial role in ensuring smooth belt operation and preventing slippage or excessive wear.

- Crankshaft Pulley: The crankshaft pulley is directly attached to the crankshaft and is responsible for driving the other pulleys and components in the accessory drive system. It is often a larger pulley compared to the accessory pulleys and serves as the starting point for power transfer through belts or chains.

In automotive systems, car pulleys are used to transmit power efficiently and reliably from the engine to various components and systems. They enable the operation of critical systems such as the electrical charging system (alternator), power steering system (power steering pump), cooling system (water pump), and air conditioning system (air conditioning compressor).

The rotation of the car pulleys is synchronized with the engine speed, allowing the driven components to operate at the appropriate speed and deliver the required performance. Proper belt tension, guided by tensioner and idler pulleys, ensures efficient power transfer and prevents belt slippage or excessive wear. Additionally, car pulleys are designed to handle the high temperatures and demanding conditions of the engine compartment.

Overall, car pulleys are essential components in automotive systems, enabling the efficient and reliable operation of auxiliary systems and ensuring the smooth functioning of a vehicle's various functions.

editor by CX

2024-04-08