Product Description

Product Description

| Type: | ALTERNATOR | Model Number | HT009-1 | Voltage | 28V |

| Current | 100A | Applications | 6BG1/6WG1/6WA1 | ||

| Pulley | 3A82 | Brand Name | KST | Certificate | IATA16949:2016 |

| OE NO.: | 8-97380-5113 | ||||

| Place of Origin | ZHangZhoug, China | Packing | Carton | Quality | 100% Tested |

Place of Origin:ZHangZhoug, China

Brand Name:KST

Warranty:1 Years

Model Number:HT009-1

Type:Alternator Assembly

Car Make:6BG1/6WG1/6WA1

Product name:Auto Alternator

Voltage:28V

Current:100A

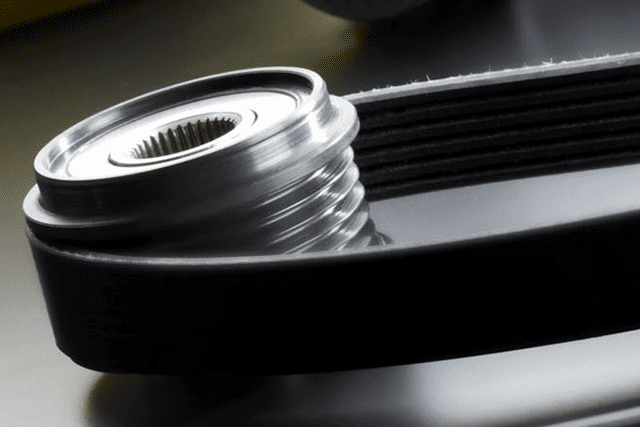

Pulley:3A82

OEM:Acceptable

Packing:Carton Box (Export Standard Packing)

Company Profile

ZHangZhoug KST auto elextric motor Co., Ltd.

Specialized in auto and heavy vehicle alternator, starter motor and parts.

Warranty is 1 year after order.

MOQ is 5 pieces.

Delievery date is about 1- 45 days after confirming the order.

ZHangZhoug KST auto elextric motor Co., Ltd. Specialized in manufacturing and exporting auto and heavy vehicle alter and starter motor, and parts, Is situated 8 CHINAMFG Street, Shuige Economic Development Zone, HangZhou City, ZHangZhougProenince, near to ZheJiang port and HangZhou port, Covering a floor area of 10, 000m and a building area of over 8, 000m. Our company now has more than 100 employees with 6 engineers and over 20technicians of different kinds among them. Our company specializes in manufacturing staters and generators for heavy-duty cars and engine-ering machinery. Which are mainly applicable for such modelsas KOMATUS, HITACHI, CARTER, DAEWOO, HYUNDAI, SHINKO, MITSUBISHI

With advanced equipments for production, inspection and testing, every products manufacturing is strictly by ISO/TS16949 quality controling standard.

Welcome to send inquiry with replace NO. And OEM NO. To ZHangZhoug KST.

Certifications

Packaging & Shipping

Supply Ability

Supply Ability10000 Piece/Pieces per Month

Packaging & Delivery

Packaging Details

Neutral package

KST package

Customize package

Port: HangZhou/Shangha

Product Description

FAQ

Q: Are you a factory or trading company?

A: We are a professional factory and specializes in the manufacture of starters and generators for heavy-duty vehicles and construction machinery.

Q.What is your terms of packing?

A:Generally, we pack our goods in neutral white boxes and brown cartons. If you have legally registered patent,

we can pack the goods in your branded boxes after getting your authorization letters.

Q.Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery.

Q.What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and

the courier cost.

Q:How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them,

no matter where they come from.

|

Shipping Cost:

Estimated freight per unit. |

To be negotiated |

|---|

| After-sales Service: | 1year |

|---|---|

| Warranty: | 1year |

| Type: | Head Cover |

| Customization: |

Available

| Customized Request |

|---|

What safety considerations should be kept in mind when working with car pulleys?

Working with car pulleys involves potential hazards, and it's crucial to prioritize safety to prevent accidents or injuries. Here are some important safety considerations to keep in mind when working with car pulleys:

- Personal Protective Equipment (PPE): Always wear appropriate personal protective equipment, such as safety glasses/goggles, gloves, and protective clothing. PPE helps protect against potential hazards like flying debris, sharp edges, or chemical exposures. Ensure that your PPE is in good condition and fits properly.

- Engine Shutdown and Cooling: Before working with car pulleys, ensure that the engine is shut off and has had sufficient time to cool down. Hot engine components, including pulleys, can cause burns or other injuries. Allow the engine to cool to a safe temperature before carrying out any maintenance or repair work.

- Secure the Vehicle: Park the vehicle on a level surface and engage the parking brake to prevent any unintended movement. If necessary, use wheel chocks to further secure the vehicle and prevent rolling. Working on a stable and stationary vehicle minimizes the risk of accidents or injuries caused by unexpected vehicle movement.

- Disconnect the Battery: When working with pulleys connected to the electrical system, such as alternator pulleys, it's advisable to disconnect the vehicle's battery. This precaution helps prevent electrical shocks or short circuits. Refer to the vehicle's manual for specific instructions on disconnecting the battery safely.

- Use Proper Tools and Equipment: Ensure that you have the appropriate tools and equipment for the task at hand. Using improper tools or makeshift solutions can lead to accidents or damage to the pulley system. Follow the manufacturer's recommendations and instructions when using tools and equipment.

- Pulley Tension Release: If you need to release tension from a pulley, such as when removing a belt, follow the manufacturer's guidelines or repair manual instructions. Improperly releasing tension can cause sudden movements or accidents. Use the appropriate tools or techniques to release tension safely.

- Pulley Alignment: When installing or replacing pulleys, ensure proper alignment with other components, such as belts, accessories, or pulley grooves. Misaligned pulleys can cause belt slippage, improper power transmission, or premature component wear. Follow the manufacturer's instructions or consult a professional to ensure correct pulley alignment.

- Avoid Excessive Force: Use caution and avoid applying excessive force when working with pulleys. Excessive force can lead to sudden movements, component damage, or personal injury. If a pulley or component is difficult to remove or install, reassess the procedure and seek guidance if necessary.

- Proper Lifting Techniques: When lifting heavy pulleys or components, use proper lifting techniques to avoid strain or injury. Lift with your legs, not your back, and ask for assistance if needed. Use lifting equipment or devices when appropriate to ensure safe handling of heavy pulleys.

- Follow Repair Procedures: Adhere to proper repair procedures outlined in the vehicle's repair manual or manufacturer's guidelines. Following correct procedures ensures safe and effective repair or maintenance work. If you are unsure about any step, consult an experienced professional or seek guidance from reliable sources.

Remember, safety should always be the top priority when working with car pulleys or any other automotive components. By following these safety considerations and exercising caution, you can minimize the risk of accidents, injuries, or damage to the vehicle or yourself.

Can car pulleys be upgraded or replaced to enhance engine performance?

Yes, car pulleys can be upgraded or replaced to enhance engine performance. Upgrading or replacing pulleys is a common modification made by automotive enthusiasts and performance-oriented vehicle owners. Here's a detailed explanation of how car pulleys can be upgraded or replaced to enhance engine performance:

- Lightweight Pulleys: One popular upgrade is the installation of lightweight pulleys. Lightweight pulleys are typically made from materials like aluminum or other high-strength alloys. By reducing the weight of the pulleys, rotational inertia is decreased, resulting in improved throttle response and faster revving. Lighter pulleys can also reduce parasitic drag on the engine, allowing more power to be transferred to the wheels.

- Performance Pulley Designs: Performance-oriented pulley designs may feature altered dimensions or profiles, such as different groove configurations or diameter ratios. These modifications aim to optimize power delivery, torque characteristics, or specific RPM ranges. Performance pulleys are designed to enhance engine performance in terms of horsepower, torque, or overall responsiveness.

- Underdrive Pulley Kits: Underdrive pulley kits are aftermarket upgrades that incorporate a combination of smaller diameter pulleys for various driven components, such as the alternator, power steering pump, and water pump. These pulleys are designed to reduce the speed at which these accessories operate, reducing their power consumption and freeing up engine power for increased performance.

- Custom Pulley Tuning: Some vehicles may benefit from custom pulley tuning, where pulley sizes or ratios are modified based on the specific requirements and goals of the engine. This tuning process involves careful analysis, calculation, and adjustment of the pulley sizes to optimize power delivery, boost efficiency, or achieve specific performance objectives.

- Supercharger or Turbocharger Pulleys: In forced induction systems like superchargers or turbochargers, pulleys play a crucial role in controlling the boost pressure and overall performance. Upgrading or replacing the pulleys in these systems can allow for increased boost levels, resulting in higher horsepower and torque outputs. However, it's important to ensure that the engine and supporting components can handle the increased stress and demands associated with higher boost levels.

- Professional Installation and Tuning: Upgrading or replacing car pulleys for performance purposes often requires professional installation and tuning. Proper installation ensures that the pulleys are correctly aligned, securely mounted, and compatible with the engine and driven components. Additionally, tuning may be necessary to optimize the engine's performance parameters and ensure safe and reliable operation.

In summary, car pulleys can be upgraded or replaced to enhance engine performance. Upgrades may include lightweight pulleys, performance pulley designs, underdrive pulley kits, custom pulley tuning, or specific modifications for forced induction systems. It's important to consider the compatibility, installation, and tuning requirements associated with pulley upgrades to achieve the desired performance enhancements safely and effectively.

What are the advantages of using high-quality pulleys in car engines?

Using high-quality pulleys in car engines offers several advantages that contribute to the overall performance, reliability, and efficiency of the vehicle. Here are the key benefits of using high-quality pulleys:

- Enhanced Durability: High-quality pulleys are built to withstand the demanding operating conditions within car engines. They are constructed using durable materials and undergo rigorous manufacturing processes, ensuring they can endure high temperatures, vibrations, and mechanical stresses. Improved durability reduces the likelihood of pulley failure, prolongs their lifespan, and minimizes the need for frequent replacements.

- Optimized Power Transmission: High-quality pulleys are designed to provide efficient power transmission from the engine to driven components. They have precise dimensions, well-engineered grooves, and optimal surface finishes that enable proper belt engagement and reduce slippage. Efficient power transmission ensures that the driven components receive the power they require, resulting in improved overall performance and functionality of the engine.

- Reduced Noise and Vibration: High-quality pulleys are carefully balanced and engineered to minimize noise and vibration. They undergo stringent quality control measures to ensure smooth operation and minimize unwanted vibrations that can cause noise and discomfort. Reduced noise and vibration contribute to a quieter and more comfortable driving experience.

- Improved Belt Life: High-quality pulleys help extend the life of belts connected to them. The precise design and smooth surfaces of these pulleys reduce friction and wear on the belts, resulting in increased belt longevity. By minimizing belt wear, high-quality pulleys reduce the risk of belt failure, improve reliability, and decrease maintenance costs associated with belt replacements.

- Precision and Accuracy: High-quality pulleys are manufactured to strict tolerances, ensuring precision and accuracy in their dimensions and performance. This precision helps maintain proper belt alignment, tension, and synchronization. Precise pulleys ensure that the belts operate optimally, preventing misalignment, slippage, or timing errors, which can negatively impact engine performance and potentially cause damage to components.

- Efficient System Operation: The use of high-quality pulleys promotes efficient operation of various engine systems and accessories. By providing reliable power transmission and proper belt engagement, these pulleys contribute to the effective functioning of systems such as the alternator, power steering, air conditioning, and water pump. Efficient system operation enhances overall vehicle performance, fuel efficiency, and driver satisfaction.

In summary, high-quality pulleys in car engines offer advantages such as enhanced durability, optimized power transmission, reduced noise and vibration, improved belt life, precision and accuracy, and efficient system operation. Investing in high-quality pulleys ensures the long-term reliability, performance, and efficiency of the engine and contributes to a smoother and more enjoyable driving experience.

editor by CX