Product Description

Company Profile

HangZhou Doerbee International Trade Co. , Ltd. , located in HangZhou hi-tech Development Zone, ZheJiang Province, the company's main auto parts, mechanical and electrical supplies. Our company has established long-term and stable cooperative relations with many auto parts factories in ZHangZhoug and ZheJiang provinces. We value credit, abide by contracts, guarantee product quality, win the trust of our customers, and make every effort to follow their needs, continuous product innovation and service improvement. OEM, sample can be customized. We will gradually improve the product types and details, if you have non-standard products need us to help you find Chinese manufacturers, please contact us, send samples, we will be your most responsible and professional partner in China. Looking CHINAMFG to working with you.

Every month, we will go back and forth to each auto parts manufacturer to find and compare all kinds of high quality and low price products for you. If you have samples, but can not confirm the model or name, you can also send samples to us, we will try our best to find out the sample manufacturers in China, compare the quality for you, and provide quotation. We represent all kinds of auto parts and mechanical and electrical products, in the future we will continue to improve the product category, please pay attention to us, any need, please feel free to contact us. At present, there are more than 3.3

Q1. How to buy?

A1:Large quantity for more discount : Inquiry → Quotation → Price resonable → Check with specification → Proforma Invoice sent → Payment made → Product shipment → Customer

Q2. What is your terms of payment?

A2:T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages before you pay the balance.

Q3. How about your delivery time?

A3:Generally, it will take 20 to 40 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q4. Can you produce according to the samples?

A4:Yes, we can produce by your samples or technical drawings.

Q5. What is your sample policy?

A5:We can supply the sample if we have ready parts in stock, but the customers have to pay the sample and courier cost.

Q6. Do you test all your goods before delivery?

A6:Yes, We will take 100% testing and photos before delivery, and keep communication with you at any time.

Q7: How do you make our business long-term and good relationship?

A7:We are not only partners, but also friends. We will try our best to provide you with the most cost-effective products. If you have any goods that are difficult to purchase, we will try our best to find them in China. We will become your most trusted buyers in China.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | 100000 Km |

|---|---|

| Warranty: | 2 Years |

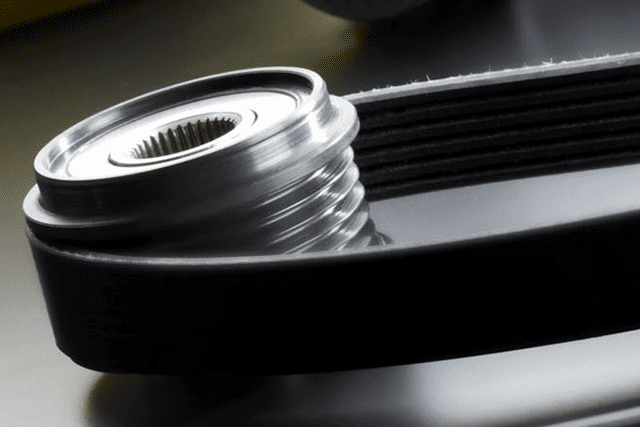

| Type: | Auto Clutch Bearing |

| Material: | Carbon Steel |

| Tolerance: | P5 |

| Certification: | TS16949 |

| Samples: |

US$ 8/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Are there different types of car pulleys, and how do they vary in applications?

Yes, there are different types of car pulleys, and they vary in applications based on their design, function, and the components they are connected to. Here's a detailed explanation of the different types of car pulleys and their varying applications:

- Idler Pulleys: Idler pulleys are stationary pulleys that guide and route the belt in a specific path. They are designed to maintain tension in the belt and ensure proper alignment between the driving and driven pulleys. Idler pulleys are commonly used in serpentine belt systems to guide the belt around various accessories, such as the alternator, power steering pump, and air conditioning compressor.

- Tensioner Pulleys: Tensioner pulleys are similar to idler pulleys but include a built-in mechanism to automatically maintain proper belt tension. They are commonly used in serpentine belt systems to provide constant tension on the belt, compensating for belt stretch and wear. Tensioner pulleys help prevent belt slippage, ensure efficient power transmission, and reduce the need for manual belt adjustments.

- Crankshaft Pulleys: Crankshaft pulleys are connected to the engine's crankshaft and are responsible for transmitting power from the engine to various accessories or components. They are usually larger in size and serve as the main driving pulleys in the engine's accessory drive system. Crankshaft pulleys are typically connected to the alternator, power steering pump, air conditioning compressor, and water pump.

- Supercharger Pulleys: Supercharger pulleys are specific to vehicles equipped with supercharger systems. These pulleys are connected to the supercharger and help drive it to compress the incoming air, resulting in increased engine performance. Supercharger pulleys come in different sizes or diameters, allowing for adjustments to the supercharger's speed and boost levels, which directly influences engine power output.

- Turbocharger Pulleys: Turbocharger pulleys are specific to vehicles equipped with turbocharger systems. Similar to supercharger pulleys, they are connected to the turbocharger and drive its turbine wheel using exhaust gases. Turbocharger pulleys, often referred to as turbine housings, come in various sizes and designs to optimize turbocharger spooling characteristics, boost levels, and overall performance.

- Accessory Pulleys: Accessory pulleys are connected to individual accessories in the engine's accessory drive system, such as the alternator, power steering pump, air conditioning compressor, and water pump. They transmit power from the crankshaft pulley to these components, allowing them to operate and perform their respective functions. Accessory pulleys may have different sizes, groove configurations, or designs based on the specific accessory they are driving.

The varying types of car pulleys mentioned above have specific applications within the vehicle's engine system. Idler pulleys and tensioner pulleys help guide and maintain proper tension in the belts, ensuring efficient power transmission. Crankshaft pulleys serve as the main driving pulleys, connecting the crankshaft to the engine's accessories. Supercharger and turbocharger pulleys are specific to forced induction systems, boosting engine performance. Accessory pulleys are connected to individual accessories, allowing them to operate and perform their intended functions.

It's important to note that the specific types and applications of car pulleys may vary depending on the vehicle make, model, and engine configuration. Manufacturers design and select pulleys based on the specific requirements and characteristics of the engine system.

How are car pulleys customized for specific makes and models of vehicles?

Car pulleys are customized to fit specific makes and models of vehicles to ensure proper compatibility, functionality, and performance. The customization process involves considerations such as the engine design, layout, accessory requirements, and desired performance characteristics. Here's a detailed explanation of how car pulleys are customized for specific makes and models of vehicles:

- Engine Specifications: Car pulleys are designed to match the specific engine specifications of each vehicle make and model. This includes considerations such as the number of cylinders, engine displacement, and power output. The pulley's size, shape, and weight distribution are tailored to accommodate the engine's physical dimensions and characteristics.

- Belt Routing: The pulleys are customized to align with the belt routing requirements of each vehicle. The placement and orientation of pulleys are carefully designed to ensure efficient and proper belt engagement with driven components. Belt routing may vary between different engine layouts (e.g., transverse or longitudinal), and the pulleys are adjusted accordingly to accommodate the specific routing needs of each vehicle.

- Accessory Compatibility: Car pulleys are customized to accommodate the specific accessory requirements of each vehicle. Different vehicles may have varying numbers and types of accessories, such as alternators, power steering pumps, air conditioning compressors, and water pumps. The pulleys are designed to match the specifications and power requirements of these accessories, ensuring compatibility and optimal performance.

- Tension and Load Requirements: Pulleys are customized to handle the specific tension and load requirements of each vehicle's engine and accessories. Factors such as belt tension, load forces, and operating conditions are taken into account during the customization process. The pulleys are engineered to withstand the anticipated loads and maintain proper belt tension to ensure reliable power transmission and prevent slippage.

- Performance Considerations: Car pulleys can be customized to achieve specific performance goals for each vehicle make and model. Performance-oriented vehicles may require pulleys designed to optimize power delivery, torque characteristics, or specific RPM ranges. Customization can involve adjusting the pulley sizes, ratios, or designs to fine-tune the engine's performance and meet the desired performance objectives.

- Manufacturing and Quality Control: The customization of car pulleys involves precise manufacturing processes to ensure accurate dimensions, tolerances, and material specifications. Pulleys are manufactured to meet the quality and performance standards required by the vehicle manufacturer. Strict quality control measures are implemented to verify the pulleys' performance, durability, and compatibility with the specific makes and models of vehicles.

In conclusion, car pulleys are customized for specific makes and models of vehicles through considerations such as engine specifications, belt routing, accessory compatibility, tension and load requirements, performance objectives, and meticulous manufacturing processes. Customized pulleys play a vital role in ensuring proper fitment, reliable power transmission, and optimal performance of the engine and its driven components. By tailoring the pulleys to the specific requirements of each vehicle, manufacturers can optimize performance, efficiency, and overall vehicle functionality.

How do car pulleys contribute to the proper functioning of the engine?

Car pulleys play a crucial role in ensuring the proper functioning of the engine. Their contribution is vital for power transmission, belt guidance, load adaptation, and accessory operation. Here's a detailed explanation of how car pulleys contribute to the engine's proper functioning:

- Power Transmission: Car pulleys are integral for power transmission within the engine. The crankshaft pulley, connected directly to the engine's crankshaft, serves as the starting point for power transfer. As the engine rotates, the crankshaft pulley rotates, transmitting power to other components and systems through belts or chains. This power transmission enables the engine to drive various systems, such as the alternator, water pump, power steering pump, and air conditioning compressor.

- Belt Guidance: Pulleys provide guidance for belts within the engine. The grooved rim on the pulleys serves as a track for the belts, ensuring they remain properly seated and aligned during operation. By guiding the belts, pulleys prevent slippage and ensure efficient power transfer. Proper belt guidance is essential for maintaining the synchronization between the engine's crankshaft and driven components, such as the camshaft(s) in an overhead camshaft engine.

- Load Adaptation: Car pulleys allow for load adaptation within the engine. Load adaptation refers to the adjustment of the effective diameter or speed ratio of pulleys to optimize power delivery based on the engine's operating conditions. Variable pulleys or movable flanges can be used to adjust the position of belts or chains, enabling the engine to adapt to varying load demands. Load adaptation ensures that the engine operates efficiently and delivers the required power for different driving situations and loads.

- Accessory Operation: Car pulleys are essential for the operation of various engine accessories. The engine's accessory pulleys, driven by the crankshaft, transmit power to components such as the alternator, power steering pump, air conditioning compressor, and water pump. These accessories are vital for electrical generation, power steering assistance, air conditioning, and coolant circulation, respectively. The pulleys ensure that the accessories operate synchronously with the engine, enabling their proper functioning.

Overall, car pulleys contribute significantly to the proper functioning of the engine by facilitating power transmission, guiding belts, adapting to load conditions, and enabling the operation of essential accessories. Their role ensures that the engine operates efficiently, delivers power to various systems, and functions reliably under different driving conditions.

editor by CX

2024-05-08