Product Description

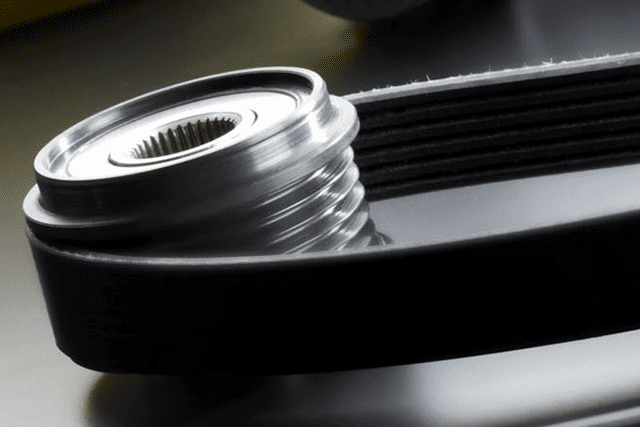

Detailed Photos

Product Description

| Item No. | Door and Window Plastic Bearing Pulley |

| Dimensions | OEM ODM |

| Material | Bearing -Chrome steel, carbon steel, stainless steel Plastic part- POM/ Nylon6 /Nylon66 +GF/PU/Rubber Housing part - Plastic(Nylon)/ Steel/ Zinc alloy die casting / Aluminium profile/ alu. Alloy die casting |

| Color | Original/black/white/Red/ Green/ Orange, or per customers' requirement |

| Surface Treatment | Zinc plated/Nickle Plated/Black treatment/ Painting/Electrophoretic treatment |

| Features | heavy-duty,adjustable,low noise,easy installation,sliding smoothly,long life,standard,customized,etc. |

| Application | Sliding window and door, Sliding accessories, furniture accessories etc. |

| Packaing | Foil bag+Neutral Carton+Pallet, or per customers' requirement |

| MOQ | 1000 pcs |

| Lead Time | According to the order q'ty |

| OEM& ODM | Technical drawing or sample is needed |

Company Profile

ABOUT US

Haibite was set up in 1996 and located at HangZhou, a beautiful city in China. Our company is bearing manufacturer&bearing distributor. Since it was first established, CHINAMFG was dedicated in research, development and manufacture of bearings. Now, CHINAMFG has become main and 1 of the first grade suppliers of all kinds of bearings. We could develop the products constructed from different materials, structures, shapes, colors etc.

WELCOME TO THE CLUB!

1. Our rollers are in stable quality with smooth rotation, long life operation, small movement, advanced injection technology engineering etc.

2. The Adjustable Rollers with smooth and long lasting operation, higher performing features like wider adjustment ranges, long rolling life performance, easy installment. It's available in multiple housing choices with any wheels to fit different aluminnum. Our roller ensure alignment across the full adjustment ranges within built-in retention system.

3. The customized hardware, like plastic parts, stamping patrs, cold forging steel patrs are widely applied in the window and doors, furniture, householders, transmission system, industrial drive system etc.

We are constantly improving and striving for excellent service. We hold a very high regard for our customers, the quality of our products, and our level of customer service.

FAQ

1. who are we?

We are based in ZheJiang , China, start from 2017,sell to North America(1.00%),Africa(1.00%),Western Europe(1.00%),Southern Europe(1.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Bearing cage,Bearing pulley,Plastic products,Miniature bearing,Needle roller bearing

4. why should you buy from us not from other suppliers?

Hardware pulley source factory,20 years professional bearing pulley experience

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW;

Accepted Payment Currency:USD,EUR,JPY,CNY;

Accepted Payment Type: T/T,L/C,D/P D/A;

Language Spoken:English,Chinese,Spanish,Japanese,F

Our Advantages

Sliding glass doors are becoming more and more popular, because of the view and natural lighting that they provide. But there can be some difficulty when it comes to maintaine them, such as the rollers have worn out. The key part is knowing which roller matches the original. Many people believe that alternatives can be found by identifying the door manufacturer individually. Actually, Most rollers are generic and used by various door manufacturers.

As the professional manufacturer of sliding rollers, we use various identifying characteristics to determine the best replacement option for your door. In addition to the number of wheels your roller uses to support the door, the presence of dimples, bumps, cut-outs and flared edges on the rollers housing will narrow down replacement options substantially. The way that the assembly installs in the door frame is also vital. The key dimensions to confirm a replacement include the width and height of the roller's outer housing, as well as the diameter of the wheel. In addition to the diameter of the wheels, the material that they're made of, steel or nylon, is also a factor. Long-term, metal wheels are known to hold up better but they can also cause the track to wear out faster, especially on heavy doors. Nylon wheels tend to be kinder to the track but may not last as long as their steel counterparts.

Purchase Notice

1.Pls send us an inquiry or leave us a message, there will be a dedicated staff to serve you within 1 hours.

2.You can ask us to take actual photos of the products for you, and free samples would be provided.

3. Welcome to visit our factory to negotiate orders, we will do our best to protect the safety of your business journey.

4. Packaging can be customized according to customer requirements

Finally, Please be sure to click "Contact supplier" to contact us, or "Call us" with any questions that you may have.

| Certification: | CE, ISO |

|---|---|

| Pulley Sizes: | Type F |

| Manufacturing Process: | Casting |

| Samples: |

US$ 0.01/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What safety considerations should be kept in mind when working with car pulleys?

Working with car pulleys involves potential hazards, and it's crucial to prioritize safety to prevent accidents or injuries. Here are some important safety considerations to keep in mind when working with car pulleys:

- Personal Protective Equipment (PPE): Always wear appropriate personal protective equipment, such as safety glasses/goggles, gloves, and protective clothing. PPE helps protect against potential hazards like flying debris, sharp edges, or chemical exposures. Ensure that your PPE is in good condition and fits properly.

- Engine Shutdown and Cooling: Before working with car pulleys, ensure that the engine is shut off and has had sufficient time to cool down. Hot engine components, including pulleys, can cause burns or other injuries. Allow the engine to cool to a safe temperature before carrying out any maintenance or repair work.

- Secure the Vehicle: Park the vehicle on a level surface and engage the parking brake to prevent any unintended movement. If necessary, use wheel chocks to further secure the vehicle and prevent rolling. Working on a stable and stationary vehicle minimizes the risk of accidents or injuries caused by unexpected vehicle movement.

- Disconnect the Battery: When working with pulleys connected to the electrical system, such as alternator pulleys, it's advisable to disconnect the vehicle's battery. This precaution helps prevent electrical shocks or short circuits. Refer to the vehicle's manual for specific instructions on disconnecting the battery safely.

- Use Proper Tools and Equipment: Ensure that you have the appropriate tools and equipment for the task at hand. Using improper tools or makeshift solutions can lead to accidents or damage to the pulley system. Follow the manufacturer's recommendations and instructions when using tools and equipment.

- Pulley Tension Release: If you need to release tension from a pulley, such as when removing a belt, follow the manufacturer's guidelines or repair manual instructions. Improperly releasing tension can cause sudden movements or accidents. Use the appropriate tools or techniques to release tension safely.

- Pulley Alignment: When installing or replacing pulleys, ensure proper alignment with other components, such as belts, accessories, or pulley grooves. Misaligned pulleys can cause belt slippage, improper power transmission, or premature component wear. Follow the manufacturer's instructions or consult a professional to ensure correct pulley alignment.

- Avoid Excessive Force: Use caution and avoid applying excessive force when working with pulleys. Excessive force can lead to sudden movements, component damage, or personal injury. If a pulley or component is difficult to remove or install, reassess the procedure and seek guidance if necessary.

- Proper Lifting Techniques: When lifting heavy pulleys or components, use proper lifting techniques to avoid strain or injury. Lift with your legs, not your back, and ask for assistance if needed. Use lifting equipment or devices when appropriate to ensure safe handling of heavy pulleys.

- Follow Repair Procedures: Adhere to proper repair procedures outlined in the vehicle's repair manual or manufacturer's guidelines. Following correct procedures ensures safe and effective repair or maintenance work. If you are unsure about any step, consult an experienced professional or seek guidance from reliable sources.

Remember, safety should always be the top priority when working with car pulleys or any other automotive components. By following these safety considerations and exercising caution, you can minimize the risk of accidents, injuries, or damage to the vehicle or yourself.

Can car pulleys be upgraded or replaced to enhance engine performance?

Yes, car pulleys can be upgraded or replaced to enhance engine performance. Upgrading or replacing pulleys is a common modification made by automotive enthusiasts and performance-oriented vehicle owners. Here's a detailed explanation of how car pulleys can be upgraded or replaced to enhance engine performance:

- Lightweight Pulleys: One popular upgrade is the installation of lightweight pulleys. Lightweight pulleys are typically made from materials like aluminum or other high-strength alloys. By reducing the weight of the pulleys, rotational inertia is decreased, resulting in improved throttle response and faster revving. Lighter pulleys can also reduce parasitic drag on the engine, allowing more power to be transferred to the wheels.

- Performance Pulley Designs: Performance-oriented pulley designs may feature altered dimensions or profiles, such as different groove configurations or diameter ratios. These modifications aim to optimize power delivery, torque characteristics, or specific RPM ranges. Performance pulleys are designed to enhance engine performance in terms of horsepower, torque, or overall responsiveness.

- Underdrive Pulley Kits: Underdrive pulley kits are aftermarket upgrades that incorporate a combination of smaller diameter pulleys for various driven components, such as the alternator, power steering pump, and water pump. These pulleys are designed to reduce the speed at which these accessories operate, reducing their power consumption and freeing up engine power for increased performance.

- Custom Pulley Tuning: Some vehicles may benefit from custom pulley tuning, where pulley sizes or ratios are modified based on the specific requirements and goals of the engine. This tuning process involves careful analysis, calculation, and adjustment of the pulley sizes to optimize power delivery, boost efficiency, or achieve specific performance objectives.

- Supercharger or Turbocharger Pulleys: In forced induction systems like superchargers or turbochargers, pulleys play a crucial role in controlling the boost pressure and overall performance. Upgrading or replacing the pulleys in these systems can allow for increased boost levels, resulting in higher horsepower and torque outputs. However, it's important to ensure that the engine and supporting components can handle the increased stress and demands associated with higher boost levels.

- Professional Installation and Tuning: Upgrading or replacing car pulleys for performance purposes often requires professional installation and tuning. Proper installation ensures that the pulleys are correctly aligned, securely mounted, and compatible with the engine and driven components. Additionally, tuning may be necessary to optimize the engine's performance parameters and ensure safe and reliable operation.

In summary, car pulleys can be upgraded or replaced to enhance engine performance. Upgrades may include lightweight pulleys, performance pulley designs, underdrive pulley kits, custom pulley tuning, or specific modifications for forced induction systems. It's important to consider the compatibility, installation, and tuning requirements associated with pulley upgrades to achieve the desired performance enhancements safely and effectively.

What is a car pulley, and how is it used in automotive systems?

A car pulley is a mechanical component used in automotive systems to transfer power, drive auxiliary components, and facilitate the operation of various systems within a vehicle. It is a wheel-like device with a grooved rim that is typically made of metal or composite materials. Here's a detailed explanation of the car pulley and its applications in automotive systems:

A car pulley operates based on the principles of rotational motion. It is usually mounted on the engine crankshaft, which is connected to the pistons and converts the reciprocating motion of the pistons into rotational motion. The pulley is driven by the rotational motion of the crankshaft and is connected to other components or systems through belts or chains.

There are different types of car pulleys used in automotive systems, including:

- Accessory Pulleys: These pulleys are responsible for driving various accessory components in the vehicle, such as the alternator, power steering pump, water pump, and air conditioning compressor. The accessory pulleys are typically connected to these components through belts, such as the serpentine belt or V-belts, and transfer power from the engine to operate these systems.

- Tensioner Pulleys: Tensioner pulleys are used to maintain the proper tension of belts in the automotive system. They are designed to apply tension to the belts, ensuring that they remain properly seated on the pulleys and operate smoothly. Tensioner pulleys often have built-in mechanisms, such as springs or hydraulic systems, to automatically adjust the tension and compensate for belt stretch or wear.

- Idler Pulleys: Idler pulleys are used to change the direction of a belt or provide additional support and tension to the belt. They are stationary pulleys that guide the belt around various components and help maintain proper belt alignment. Idler pulleys play a crucial role in ensuring smooth belt operation and preventing slippage or excessive wear.

- Crankshaft Pulley: The crankshaft pulley is directly attached to the crankshaft and is responsible for driving the other pulleys and components in the accessory drive system. It is often a larger pulley compared to the accessory pulleys and serves as the starting point for power transfer through belts or chains.

In automotive systems, car pulleys are used to transmit power efficiently and reliably from the engine to various components and systems. They enable the operation of critical systems such as the electrical charging system (alternator), power steering system (power steering pump), cooling system (water pump), and air conditioning system (air conditioning compressor).

The rotation of the car pulleys is synchronized with the engine speed, allowing the driven components to operate at the appropriate speed and deliver the required performance. Proper belt tension, guided by tensioner and idler pulleys, ensures efficient power transfer and prevents belt slippage or excessive wear. Additionally, car pulleys are designed to handle the high temperatures and demanding conditions of the engine compartment.

Overall, car pulleys are essential components in automotive systems, enabling the efficient and reliable operation of auxiliary systems and ensuring the smooth functioning of a vehicle's various functions.

editor by CX

2023-11-21